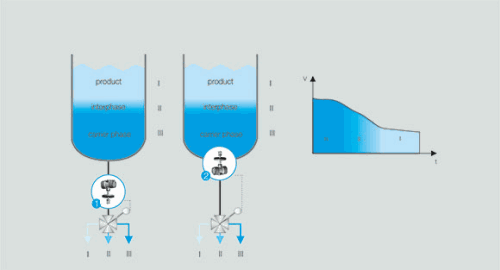

In the petrochemical industry, different product phases must be safely separated from carrier phases. This is done in both continuous procedures and in batch processes. It is often realized in batch processes by the manual switching of valves as well as visual observation of phase transitions (inspection glasses). This approach is, however, marred by unreliability.

Automation can easily be realized by the use of SensoTech’s LiquiSonic immersion sensor. The change of the sonic velocity shows a typical significant change in the signal between the individual phases. This enables LiquiSonic to supply a clear signal for the safe and reproducible separation of the product and carrier phase. The fast sensor response time allows for high separation precision which immediately results in considerable product savings. Repeated phase separations process steps are successfully avoided.

The use of LiquiSonic with continuous phase separation works in a similar way. Two sensors in the settling tank allow for the continuous control of the substance infeed as well as the phase flows that are to be separated. This allows for an improved utilization of the system, as well as an increased product yield. LiquiSonic systems have been successfully implemented in the detection and separation of:

• Fuels/water.

• Oil/salt water.

• Glycerine/bio diesel.

• Gas/liquid phases.

Unlike conductivity sensors, SensoTech’s LiquiSonic sensors may also be used in the different separation processes of watery and organic phases. The continuous measurement allows for the setting of almost any separation areas within the transition or sludge phases. The signal development can be directly observed using the controller trend view. Switching thresholds of the digital controller outputs can be parameterized. For isolated solutions, these outputs can directly switch from existing multiport valves or valve clusters.

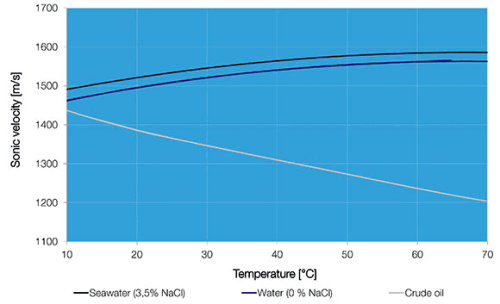

Density difference allows separation

Due to the difference in the density of oil and salt water, the two phases can be separated. The salt water is pumped out from below the oil. The separation of the salt water from the oil can be monitored by means of SensoTech’s LiquiSonic measuring technology. In this connection, the characteristic sonic velocities of the relevant phases are measured and evaluated at the controller. This allows for phase separation in a matter of seconds. Despite high flow rates, even low water and oil sections are detected and separated as quickly as possible thanks to an extremely short reaction time (< 1 second). This precise salt water separation results in an increase in the oil yield, ensuring the necessary quality for the subsequent processing in the refinery.

LiquiSonic sensors supply clear, temperature compensated concentration values for the different process liquids. In this way, the following tasks can be performed at relevant points of process engineering processes:

• Monitoring and detection of supplied products.

• Quality monitoring for intermediate products.

• Control and monitoring (dilution, concentration, product infiltrations).

• Monitoring of the end product quality.

The determination of the product type and the water content are elementary for the quality assurance of petrochemical products. LiquiSonic systems are successfully used for the detection and differentiation between heating oil, petrol, diesel, kerosene and other fuels. Additionally, the water content can be precisely determined by means of inline sonic velocity sensors and transferred to master systems by means of a selection interfaces, such as Profibus DP.

Analyzers

The LiquiSonic analyzer installs directly within any process vessel, tank, or pipe, without a costly bypass solution. By virtue of a special protective ETFE coating, the sensors work in very reactive environments, even in hydrofluoric acid. Faulty fillings and supplies of lower quality levels are successfully avoided. Water infiltrations in fuel can also be detected inline to ensure system safety.

| Email: | [email protected] |

| www: | www.sensoquad.com |

| Articles: | More information and articles about Sensoquad |

© Technews Publishing (Pty) Ltd | All Rights Reserved