SMC launches wireless valve bank in SA

July 2020

Industrial Wireless

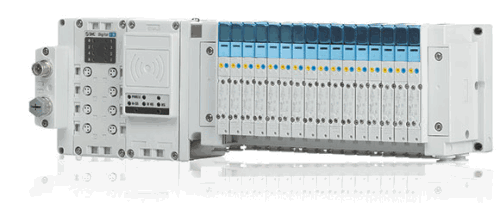

In response to customer demand for a reliable communication system, which could limit the number of cables needed to communicate between multiple valve banks/field sensors and a PLC, a wireless communication module was the only logical answer. SMC has developed such a system, the EX600-W, which has addressed all the necessary safety and interference concerns.

The module has been registered with ICASA for use on the 2,4 GHz frequency band. This falls well out of the range of any frequency disturbances generated in an industrial environment, thus negating all possible interference from welding machinery, motor drivers or electro-magnetic heating systems. Furthermore, the base and remote modules use a unique frequency hopping algorithm to provide stable communication and prevent disruptions from other electronic devices. The system is designed to work within a 10 m radius using an encrypted protocol to prevent unauthorised network access.

The EX600-W base unit makes use of Ethernet/IP or Profinet protocols and is capable of pairing with up to 127 remote modules. The base unit can handle up to a combined total of 1280 inputs and 1280 outputs. These can be distributed throughout the wireless network as required, giving complete control of the system layout.

Success stories

Numerous automotive industry customers have tested the EX600-W on their tool changers and spot welders. In over two years of test operation zero failures were reported.

SMC’s Wade Holland.

In another application, a leading developer of solutions for automotive, aerospace and the food, beverage and pharmaceutical industries, designed a compact three-station pick and place robot cell. Due to the elimination of field-based wiring, simple block diagrams replaced complex wiring plans. The elimination of communication wiring enabled the controls engineer to significantly reduce the setup and integration times, reducing the delivery time of the cell from six months to four weeks.

In a third case, SMC UK and ATG partnered with MAKE UK to design and build a state-of-the-art training facility for engineering apprentices. The 10 m radius of the EX600-W offered the perfect range for wirelessly integrating all training stations in the cell, with one base unit connected to the PLC via Ethernet/IP. This has significantly reduced the cabling costs and installation time of the various stations. Furthermore, thanks to the built-in web function of the EX600-W, all stations can be remotely monitored away from the physical infrastructure.

Further reading:

Remote water monitoring

Omniflex Remote Monitoring Specialists

Industrial Wireless

Remote monitoring specialist, Omniflex has helped New South Wales Ports improve its ability to track water usage by installing remote monitoring to 38 water meters at its Port Kembla site, sending the data to the NSWPorts web portal.

Read more...

Control and information overlay for nuclear plants

Omniflex Remote Monitoring Specialists

Industrial Wireless

Radiation monitoring specialist Omniflex has supported a major UK nuclear plant operator through a critical phase of its decommissioning programme, ensuring continuous safety and security monitoring as buildings were progressively de-manned.

Read more...

Revealing unseen leaks

Industrial Wireless

As water tariffs rise and infrastructure continues to age, utilities across the Nordic region are under growing pressure to do more with less. Mano Koolen, channel sales manager at leak detection specialist, Ovarro outlines how municipalities are responding to hidden water loss using acoustic monitoring.

Read more...

Upgrading an outdated alarm monitoring system

Omniflex Remote Monitoring Specialists

Industrial Wireless

Legacy alarm replacement specialist, Omniflex has successfully upgraded Guernsey Electricity’s MPAS90 alarm annunciator systems, which were first installed decades ago and are obsolete.

Read more...

Upgrading obsolete rack-based alarms

Omniflex Remote Monitoring Specialists

Industrial Wireless

Legacy alarm replacement specialist, Omniflex has supported a major oil and gas company in Qatar by upgrading the obsolete MPAS 90 alarm systems at one of its major plants in the country.

Read more...

Würth Elektronik presents new radio modules

Industrial Wireless

Würth Elektronik has introduced two new highly compact radio modules. They give developers maximum freedom in designing proprietary wireless solutions that go beyond standard protocols.

Read more...

Senseca introduces data loggers to meet long range transmission needs

Senseca

Industrial Wireless

Senseca has introduced the driven LR35 data logger series based on LoRaWAN technology. They are specifically designed for situations where long-range transmission is required.

Read more...

Omniflex upgrades alarms for Uganda hydro plants

Omniflex Remote Monitoring Specialists

Industrial Wireless

Omniflex has worked with Uganda Electricity Generation Company to provide an upgrade solution for the plant alarm equipment across the Nalubaale and Kiira hydroelectric power stations on Lake Victoria.

Read more...

New RFID communication module

Siemens South Africa

Industrial Wireless

The new Siemens RFID communication module, Simatic RF128C enhances efficiency and flexibility, making it ideal for applications in the battery, electronics and semiconductor industries.

Read more...

Advanced missing person locator system to boost mine safety

Industrial Wireless

Becker Mining South Africa has enhanced its state-of-the-art Missing Person Locator system, a powerful module integrated into the company’s comprehensive SmartFlow digital mine visualisation and management platform, designed to enhance emergency preparedness and personnel safety in mining operations worldwide.

Read more...