There are many applications where a standard one-colour thermometer reads the temperature incorrectly. These include:

• Small objects (too small to fill the cone-of-vision).

• Dust, smoke or steam, which obscures the line of sight.

• Windows in the process that get dirty and are difficult to keep clean.

• Emissivity of the product changes (due to changes in alloy or surface condition).

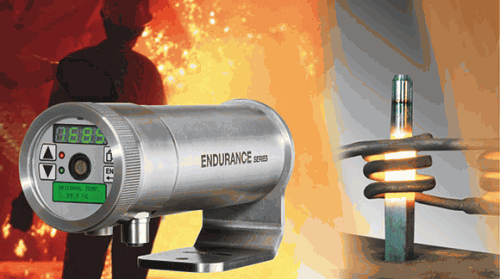

However, a two-colour or ratio pyrometer, like the Endurance by Raytek and Ircon, operates reliably, even with these problems, and indicates the correct temperature.

Theory of operation for ratio (two-colour) sensors

The two-colour ratio technology allows accurate and repeatable temperature measurements, which don’t depend on absolute radiated energy values. In use, a two-colour sensor determines temperature from the ratio of the radiated energies in two separate wavelength bands (colours). The benefit is that accurate measurements can be made under the following conditions:

• When the field of view to the target is partially blocked or obscured.

• When the target is smaller than the sensor’s field of view.

• When the target emissivity is low or changing by the same factor in both wavelength bands.

Another benefit is that two-colour sensors measure closer to the highest temperature within the measured spot (spatial peak picking) instead of an average temperature. A two-colour sensor can be mounted farther away, even if the target does not fill the resulting spot size. The convenience is that users are not forced to install the sensor at some specific distance based upon target size and the sensor’s optical resolution.

Partially obscured targets

The radiated energy from a target is, in most cases, equally reduced when objects or atmospheric materials block some portion of the optical field of view. It follows that the ratio of the energies is unaffected and thus the measured temperatures remain accurate.

A two-colour sensor is better than a one-colour sensor under the following conditions:

• Sighting paths are partially blocked (either intermittently or permanently).

• Dirt, smoke, or steam is in the atmosphere between the sensor and target.

• Measurements are made through items or areas that reduce emitted energy, such as grills, screens, small openings, or channels.

• Measurements are made through a viewing window that has unpredictable and changing infrared transmission due to accumulating dirt and/or moisture on the window surface.

• The sensor itself is subject to dirt and/or moisture accumulating on the lens surface.

Targets smaller than field of view

When a target is not large enough to fill the field of view, or if the target is moving within the field of view, radiated energies are equally reduced, but the ratio of the energies is unaffected and measured temperatures remain accurate. This remains true as long as the background temperature is much lower than the target’s. The following examples show where two-colour sensors can be used when targets are smaller than the field of view:

• Measuring wire or rod – often too narrow for field of view or moving or vibrating unpredictably. It is much easier to obtain accurate results because sighting is less critical with two-colour sensors.

• Measuring molten glass streams – often narrow and difficult to sight consistently with single-wavelength sensors.

Uncertain or changing emissivity

When target emissivity is uncertain or changing, a two-colour sensor can be more accurate than a one-colour instrument as long as the emissivity changes by the same factor in both wavelength bands. Accurate measurement results are dependent on the application and the type of material being measured. The emissivity of all real objects changes with wavelength and temperature, at varying degrees, depending on the material.

| Tel: | +27 11 608 1551 |

| Email: | [email protected] |

| www: | www.randci.co.za |

| Articles: | More information and articles about R&C Instrumentation |

© Technews Publishing (Pty) Ltd | All Rights Reserved