Deionisation of boiler feed water using an ion exchanger

November 2017

Valves, Actuators & Pump Control

In steam boiler systems, salts that have dissolved in the water lead to corrosion and deposits. To avoid this and depending on the operational mode and design of the steam generator, there are important requirements regarding the quality of the boiler feed water.

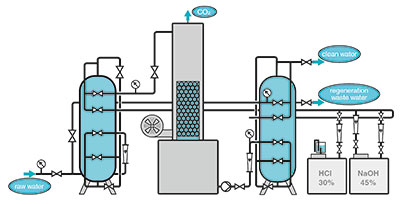

In a deionisation system, the salts that have dissolved in the water are removed using ion-exchange resins. These salts are dissociated, i.e. in positive cations and negative anions, and as a result, a so-called desalination line is set up as follows: cations exchanger – CO2 degasifier: anions exchanger – mixed-bed filter. Moreover, for the installation to operate properly, a regeneration station and neutralisation are required.

Construction and function of an ion exchanger

First, the water that is to be desalinated flows through the acid resin bed of the cations exchanger. Here, the cations (e.g. calcium (Ca2+), magnesium (Mg2+), sodium (Na+)) are replaced by H+ ions, which have been absorbed onto the resin. During this process, carbon dioxide, among other things, is produced.

CO2 degasifier: The free CO2 is dissolved in a secondary CO2 degasifier. Due to the expansion element, there is a high level of recirculation on the water‘s surface, and as a result, the gaseous CO2 is released. Fewer HCO3 ions are now generated, and therefore the secondary anions exchanger is discharged and the chemical and regeneration water consumption is lowered.

Anions exchanger: Here, the anions (e.g. hydrocarbonate (HCO3(-)), sulphate (SO42-) or chloride (Cl-) are replaced with hydroxide ions (OH-)), which have been adsorbed on the alkaline resin bed of the anions exchanger.

Mixed-bed filter: The secondary mixed-bed filter, also called a polisher, removes the residual ions from the water. It contains both highly acidic and highly alkaline ion-exchanger resins. By mixing the two resins, the residual ions can be completely removed.

Regeneration

When the ion-exchanger resins are completely depleted, they are regenerated. During this process, the acidic resin from the cations exchanger is flushed with hydro-chloric acid (HCl) and the alkaline resin from the anions exchanger is flushed with sodium hydroxide (NaOH). If there is still residual acid or alkali in the regeneration wastewater, it must be neutralised before it drains off into the sewage system.

So that pure water can be generated continuously, two desalination lines are required – one is in operation and the other is part of the regeneration phase.

Operational mode

The ion-exchanger resins are available as a suspended or fixed bed, or also as a combined suspended bed with a fixed bed section. Most commonly, regeneration takes place in counter current, i.e. charging occurs in one direction and regeneration occurs in the other. Generally, charging occurs from bottom to top and flushing occurs from top to bottom. Compared with the direct current method, a significantly higher product quality is achieved and fewer regeneration agents are consumed.

The GEMÜ solution

To dose acids and alkalis, and to distribute the water, the GEMÜ R690 and R677 diaphragm valves are used, which have nominal sizes of DN20 – DN50, EPDM as diaphragm material and a GEMÜ 805 variable area flowmeter. The valves are also equipped with GEMÜ 1235 electrical position indicators.

For more information contact GEMÜ Valves Africa, +27 (0)11 462 7795, [email protected], www.gemue.co.za

Further reading:

Compact valve position indicator

Emerson Automation Solutions

Valves, Actuators & Pump Control

Emerson’s new TopWorx DVR Switchbox is an entry-level addition to the DV Series of valve position indicators. It combines a durable resin enclosure, compact size, and a patented cam design that provides a reliable valve position feedback for water and wastewater systems, food and beverage production lines, and industrial utilities.

Read more...

Dependable pumping for dewatering in hard rock mining areas

Valves, Actuators & Pump Control

Becker Mining’s Pumpor Vertical Spindle (PVS) pumps are hard at work on many mines throughout Africa, with many units installed recently in the Carletonville area, West of Johannesburg.

Read more...

Efficient, affordable solution for electrohydraulic pumps

Parker Hannifin - Sales Company South Africa

Valves, Actuators & Pump Control

In the world of construction a revolution is changing the status quo, the electrification of small and efficient construction machinery.

Read more...

Redefining Industrial Automation with the new Festo Valve Terminal

Festo South Africa

Valves, Actuators & Pump Control

Festo recently introduced its latest innovation in the form of the Valve Terminal VTUX. This invention marks the beginning of a new era in valve terminals, with its features making it an impressive solution for the future.

Read more...

New pilot-operated relief valve

Emerson Automation Solutions

Valves, Actuators & Pump Control

Emerson has introduced a pilot-operated relief valve for installation on pressurised bullet tanks used to store liquid propane and anhydrous ammonia. This type of pressure relief valve is typically installed on tanks fabricated by OEMs for end users, engineering firms, or contractor customers.

Read more...

Pulse valves for dust collection

Emerson Automation Solutions

Valves, Actuators & Pump Control

In process manufacturing, especially hard mineral mining, dust particles are unavoidable. If this pervasive dust is not effectively removed, it can accumulate throughout mines, plants and other facilities, becoming hazardous to workers and equipment.

Read more...

Case History 191: The weakest link.

Michael Brown Control Engineering

Valves, Actuators & Pump Control

Which is the weakest link in a control loop? The answer, without any doubt is that, in most cases, the final control element is the weakest link.

Read more...

High-flow solenoid valve

Emerson Automation Solutions

Valves, Actuators & Pump Control

Emerson has introduced the new ASCO Series 327C solenoid valve, which features a direct-acting, high-flow design that provides superior flow-to-power ratio. It permits high flows at minimum power levels, making it ideal for use in power plants, refineries, and chemical processing facilities.

Read more...

Selection of two-port valves: an open and shut case

SMC Corporation South Africa

Valves, Actuators & Pump Control

Little consideration is generally given to two-port valves because they are often perceived as simple devices that only open and close to control downstream fluid supply. Although this is mechanically true, choosing the optimal two-port valve for your application can make a big difference, saving space, weight and energy consumption.

Read more...

Emerson software optimises maintenance

Emerson Automation Solutions

Valves, Actuators & Pump Control

Emerson has announced the Plantweb Insight Valve Health Application, a powerful software tool that combines Fisher control valve expertise with advanced analytic algorithms. The new app makes it possible for users to visualise an entire connected fleet of valves, while prioritising actions based on the health index of each valve.

Read more...