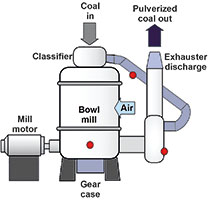

Many coal-fired power plants measure various pressures associated with their coal pulverising mills. The red dots in Figure 1 show the typical locations for these measurements for a Raymond Bowl type mill in the pulverising mill section (the ductwork from the classifier carrying coal fines to the exhauster) and the exhauster (the fan and ductwork carrying pulverised coal and fines to the boiler burners).

Optimising mill operation

A certain ‘sweet spot’ of pressure indicates smooth and proper operation of the mill, as well as the exhauster ductwork. The impulse lines that transfer the pressure signal to a rack of transmitters may be long – 10 to 20 metres in some cases. The sensed pressure is usually in the range of 7 to 10 kPa.

If the pressure drops, the mill could be plugged and the fuel supply cut short; higher than normal pressure may indicate plugging of downstream coal ducts leading to the furnace. Improper pressures often lead to flame instability, productivity losses and unnecessary pollution.

Dealing with plugged impulse lines

Plant maintenance operations often have to deal with problems associated with the long impulse lines that run to the pressure transmitters. The lines may plug as often as once a week, and even once a shift in some cases. A small air purging system in the sensing line may be present to provide positive pressure, attempting to keep the coal out of the sensing line. However, wet coal, following a rainstorm for example, invariably leads to plugged lines. In the worst cases, maintenance technicians have to drill out impulse lines plugged with dried ‘mud’.

Ideally, the pressure would be sensed directly, with the transmitter mounted on the mill, exhauster or ductwork. This arrangement would eliminate the need for long, narrow impulse lines, but the pressure sensing diaphragm would have to withstand the severe abrasive effects from high velocity pulverised coal.

The ABB solution: Diaflex coated diaphragm

This application calls for a transmitter with a direct-mount seal and non-standard pressure diaphragm that can withstand the severe abrasive effects from high-velocity pulverised coal. ABB’s 2600T direct-mount seal pressure transmitters are available with diaphragms protected by a patented Diaflex coating: a nano-structured material which has hardness similar to that of diamond. The coated diaphragms may be mounted flush or extended to reach the processing area.

Diaflex consists of a quaternary coating based on titanium and silicon (SiTiN) of the nitrides class. Using a process called physical vapour deposition, ABB coats the transmitter’s 316L stainless steel diaphragm seal to a thickness ranging from 3 to 5 m. This deposition technique and thickness provide the necessary flexing sensitivity for accurate pressure measurement, while at the same time protecting the diaphragm from the abrasive effects of high velocity coal particles.

ABB’s welded remote seal technology adds superior performance and reliability. The physical characteristics of Diaflex remain stable between -100 and 700°C, but the transmitter’s maximum working process temperatures are limited by the fill fluid.

Diaflex coated diaphragms have proved their durability in this application. Installation has resulted in significant savings in maintenance hours, and more efficient burner management.

For more information contact ABB South Africa, +27 (0)10 202 5000, [email protected], www.abb.com/instrumentation

| Tel: | +27 10 202 5000 |

| Fax: | +27 11 579 8441 |

| Email: | [email protected] |

| www: | www.abb.com/za |

| Articles: | More information and articles about ABB South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved