Click here for .pdf file.

End-user details

Name: Details withheld at reviewer request

SI details

Name: Not provided

Designation: Engineer

Company: GE Industrial Solutions

Product details

Product names and versions: Proficy CIMPLICITY HMI/SCADA 8.2; Proficy GlobalView 8.2; Proficy Historian 4.5

Vendor: GE Intelligent Platforms

Phone: +27 (0)11 237 0000

E-mail: [email protected]

URL: www.ge-ip.com

Application details

Location: Vanderbijlpark, Gauteng

Industry: Metals

Application: Manufacturing

Server OS: Windows Server 2000

Client OS: Windows XP Professional 32-bit

Application statistics

Tag count: 21 000

Updates per day: 285 120 000

Front ends: 15 500 DIO and 5000 AIO across 16 front end controllers (GE Innovation, GE PLC, Siemens Simatic S7 PLC, Allen Bradley) and motor drives (Rockwell, Allen Bradley, ABB and Mitsubishi)

Licences: 1 pair * 35 000 redundant Proficy CIMPLICITY Pro Server SCADA licences; 16 * GlobalView client licences; 1 * 10 000 tag Proficy Historian Server licence

END-USER RESPONSES

General

Q: Briefly describe the application including information on any pre-existing control system.

The project involved upgrading from a previous version of Proficy CIMPLICITY to the latest version. As part of the upgrade Proficy Historian was installed.

Q: What was the primary motivation for the project?

To maintain Microsoft OS compatibility with the latest 64-bit operating systems and to benefit from the Digital Graphical Replay (DGR) feature for improved diagnostics and improved long-term archiving.

Q: What were the main goals established for the project?

1. To be able to use CIMPLICITY on newer Windows operating systems in compliance with ArcelorMittal IT policy.

2. To provide real-time visibility into operations for process control.

3. To grant more people access to view scada screens via the web.

Q: What Project Management principles and/or methodologies did you employ as end-user to mitigate risk, ensuring the pro-ject came out on time and within budget?

A dedicated project unit comprising business experts was set up to ensure the implementation of an appropriate manufacturing solution in compliance with a timetable and best service provision. The project team coordinated the various functions from project development through to the commencement of volume production.

Licensing, maintenance and support

Q: What upgrade agreements are in place for this application?

Upgrades are covered under an annually-renewable GlobalCare agreement.

Q: How is after-sales support handled on this application?

Via a paid annual support agreement which includes telephonic, e-mail and desktop remote support.

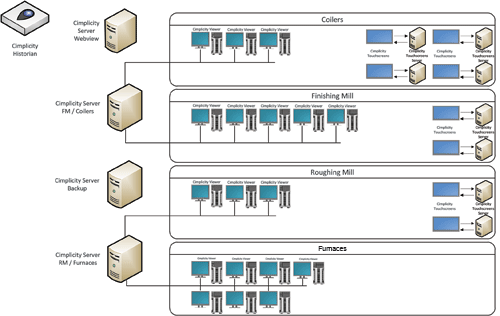

System architecture

Q: Is the scada system integrated onto an intranet or the Internet? If so, what level of remote monitoring and control is configured?

Yes, using local intranet for development, configuration and full remote control through standard desktop clients. The system can also be accessed by iPad clients for remote control and monitoring subject to user access rights.

Q: Do you run the scada in conjunction with any third-party application software (Other than MES)?

No.

Management reporting and integration

Q: Does the application include data archiving / historian capabilities with an historical data reporting system?

Yes, the application uses Proficy Historian for high speed data collection and reporting. The historian uses a Microsoft Excel add in for basic reporting.

Q: Is the system integrated with an MES / ERP or other management reporting or control system? (e.g. Baan, SAP, SYSPRO…)

No.

Q: Have any production benchmarking tools been configured as part of the scada system?

No.

Q: Has any asset management functionality been configured in the application (for software assets, control system assets or for plant assets)?

No.

Q: Has any GIS (Geographic Information Systems) functionality been configured in the application?

No.

Q: Are you using tablet PCs or mobile phones to interact with this scada system?

Yes. The Proficy SCADA app for the iPad is used to view scada screens over a wireless network. The future plan is to use Proficy RTOI to monitor asset health, analyse KPIs and drive mobile workflows.

End-user conclusion

Q: What was the predominant feature (or features) that made you decide to purchase this scada product over all others for this application?

Ease of use, support from the vendor, upgrade path, open and flexible system with mobile connectivity (including third-party apps), high speed data storage, cloud capabilities, Advanced Analytics and Predictive Analysis.

Q: What single feature most impresses you about the product now that it is in operation?

Dynamic picture updates to clients (thick, thin and mobile) from the Proficy SCADA Server.

Q: What impresses you most about the architecture?

The ease with which the architecture scales from a simple client server to a multi-tier application to a fully-fledged cloud-based interface on industry standard devices/clients.

SI RESPONSES

Project details

Q: Approximately how many man-hours did the scada configuration take?

Approximately 150 man-hours.

Q: What tools were used to minimise the man-hours taken?

SCADA Data Base (SDB) exchange utility, CIMPLICITY OPC, Kepserver, Softing OPC, OPC browser.

Q: What human factors were taken into consideration in the HMI design process?

Maintained previous standard colour usage, whilst trying to accommodate operator preferences.

Q: For the graphics development process did you use standard library images, or did you have to draw images from scratch?

Both.

Q: How would you describe the library of graphic images?

Fairly comprehensive.

Q: Did you use any ‘special’ images (e.g. photographs, 3D images, specialised dashboards, etc.)?

No.

Q: Did you use any video or multimedia technology in the application?

No.

Q: What alarm management standards or best practices were adopted in configuring the scada system alarms?

We followed the ANSI/ISA 18.2 alarm management standard.

Q: What structured processes were followed to determine expected performance under full load, and during abnormal failure conditions?

We followed manufacturer’s recommended architecture and server requirements.

Q: What are the key physical communication layers and communication protocols employed in the system?

Ethernet TCP/IP and Modbus TCP/IP over fibre.

Q: What levels of redundancy are incor-porated in this scada application?

A redundant server was implemented. On the client side there are sufficient viewers and touch screens in each area.

Q: What specific custom code or scada scripts were written for this project?

None.

Security and data protection

Q: How have authentication, authorisation and role management been configured?

Domain users are mapped to CIMPLICITY roles and resources through Windows domain integration.

Q: Does the design make provision for a DMZ and firewall segregation of process (scada) network and business networks?

The control system is on its own domain separate from the business LAN and firewalled at the interconnection.

Q: What configuration backup and data archive backup methodologies have been adopted?

Backups are run locally then the backup file is moved during low bandwidth usage to an external location.

Q: Did you use any integrated or third-party configuration control system for the scada configuration during the engineering of this application?

Yes. GE configuration tools.

SI conclusion

Q: How would you rate the ease of use of the historical reporting system?

Using the Historian is very easy and it allows for easy querying of the data for the reporting services.

Q: What impresses you the most about the engineering / configuration aspects of the product now that it is in operation?

Ease of use.

Q: What impresses you most about the architecture?

The ease with which the architecture scales, the wide range of drivers available and the ability to upgrade.

VENDOR RESPONSES

Product

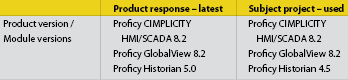

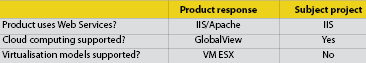

See Table 1.

Q: Vendor comments on product / modules?

Proficy CIMPLICITY HMI/SCADA is a Client/Server-based HMI/scada solution that provides process visualisation, data acquisition and supervisory control over manufacturing environments, providing a solid and reliable data foundation for digitised production management. CIMPLCITY has support for GE IP PCI based network cards allowing for sharing memory with PLC controllers or other cards providing instant access to a shared memory space.

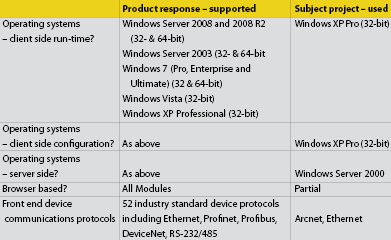

Operating systems / VMware

See Table 2.

Q: Vendor comments on operating systems

Microsoft IIS, Windows Mobile, Mobile OS, iOS and iPad client support.

Licensing, maintenance and support model

Q: What sort of licensing agreement options are offered?

* Licence is tag based with Runtime and Development server options. Clients are purchased separately.

* All systems include as standard Graphics, Alarm Management, Trending, Basic Control Engine (VB scripting), System Management Utilities, ODBC Data Logging, DDE Client, Advanced DDE Client, OPC Client and GE Intelligent Platforms PLC communications.

* CIMPLICITY Pro Server is a bundled package including multiple drivers and the following functionality: Action Calendar, Recipe, System Sentry, SQL 1 Client User, Terminal Services Single User, WebView Single User, Digital Graphic Replay, Marquee Driver and Statistical Process Control.

Other optional modules include:

* Alarm Cast Advanced / Enterprise.

* Redundancy.

* A comprehensive list of dedicated drivers for third-party data providers.

Q: Are licences sold outright or subject to periodic (e.g. annual) renewal?

Licences are a once-off purchase with the option to renew annually.

Q: What upgrade agreements are offered?

Patches and version upgrades are free for GlobalCare customers.

Q: What after-sales offerings iro support and maintenance are available, and which technologies are used to deliver them?

Support is covered under a paid annual support agreement and includes telephonic, email and desktop remote support (if access is allowed).

Technology incorporated

See Table 3.

Q: What new technology has been introduced into the product in the last 12 months?

* .NET scripting support that supports VB.NET and C #.

* Scada publishing to SOA to trigger Proficy Workflows.

* Historian Expressions Processor for direct access to historian data sources for use in animation and trending.

* Support for Apple iPad mobile clients in GlobalView 2.2.

* Alarm Change Approval (esignature).

* Support for Digital Graphical Review (DGR) over GlobalView by enabling multiple DGR sessions per computer.

* AlarmCast providing notification of events to a variety of devices including mobile phones, Blackberrys, PDAs and fixed data receivers.

* Marquee Manager for displaying data on a variety of Andon boards.

Management reporting and integration

Q: What native historical data reporting options are available?

Proficy Historian Analysis, RTIP, MS Excel, OLE DB and OPC HDA.

Q: What product specific interfaces does the product have iro well-known MES packages?

SOA, OPC DA, OPC AE, OPC HDA, OLE DB and BusinessTalk for SAP.

PLC configuration and programming

Q: What capabilities does the scada offer in terms of generation and/or management of PLC configuration files or PLC application code?

The PLC tag database, class and objects are automatically generated by the scada for Proficy PAC systems.

Security and data protection

Q: If the scada system generates application files that are transferred to the PLC, how are PLC virus attacks prevented in this process? Please elaborate.

Firewalls and antivirus systems are used to manage the communication ports.

Q: What authentication, authorisation and role management models are available for the runtime environment?

Domain or local Windows security can be used. It is defined by resource, role and user.

Unique selling proposition (USP)

Q: List the top five feature/benefit pairs that contribute to this product’s USP.

* Digital Graphical Replay (DGR) – lets users replay and analyse past events enabling them to identify and troubleshoot issues and prevent repeat occurrences.

* GlobalView – support for multi-monitor display and PC-based web browsers, Unix and Linux browsers, and mobile clients (Window CE, Windows Mobile, iPad).

* Microsecond time stamps – microsecond resolution supports detailed SOE analysis.

* Alarm Cast – provides timely notification of events to ever more mobile operators via a variety of different Internet, mobile and PC media including pagers, SMS, e-mail, ODBC and UCP.

* Historian Expression Processor – provides direct access to historian data sources to animate screen objects, or as part of the trending to provide statistical analysis for enhanced decision making.

© Technews Publishing (Pty) Ltd | All Rights Reserved