Click here for .pdf file.

End-user details

Name: Andrew Slinger

Designation: Instrumentation technician

Company: Rand Carbide

Phone: +27 (0)13 690 8386

E-mail: [email protected]

SI details

Name: Lukasz Wojtysiak

Designation: Director

Company: Luka Technologies

Phone: +27 (0)73 263 0995

E-mail: [email protected]

Product details

Product name and version: Adroit 7.0

Vendor: Adroit Technologies

Phone: +27 (0)11 658 8100

E-mail: [email protected]

URL: www.adroit.co.za

Application details

Location: Witbank, Mpumalanga

Industry: Ferrosilicon

Application: Monitoring and control

Server OS: Windows Server 2012

Client OS: Windows 7

Application statistics

Tag count: Approx. 25 000

Updates per day: Approx. 120 920 000

Front ends: 5000 DIO and 450 AIO over DeviceNet MMCs and 10 Mitsubishi Q Series PLCs

Licences: 1 * Unlimited (>25 000) Scan Point 50 * Remote Clients

END-USER RESPONSES

General

Q: Briefly describe the application including information on any pre-existing control system.

Adroit 4 was upgraded to Adroit 7 as a result of changes in Microsoft Operating Systems (OS) requirements and support.

Q: What was the primary motivation for the project?

To update an existing Adroit 4 system that was not supported on the latest Windows OS versions. New features of Adroit 7 had technology which allowed individual servers to be proxied to one central server, allowing users to connect to just that one server to view different processes.

Q: What were the main goals established for the project?

1. To develop easy to use and simple user interfaces

2. To provide increased logging history

3. To monitor and report on alarming performance

Q: What Project Management principles and/or methodologies did you employ as end-user to mitigate risk, ensuring the pro-ject came out on time and within budget?

Established a scope of work (FDS and URS), and scheduled project meetings to discuss production, engineering requirements and project progress.

Licensing, maintenance and support

Q: What upgrade agreements are in place for this application?

An annual groupwide licence upgrade.

Q: How is after-sales support handled on this application?

As part of the groupwide licence, engineering and support hours are available for support and engineering assistance on an annual basis as required. After each site visit a system audit is performed by Adroit engineers to check system status.

System architecture

Q: Is the scada system integrated onto an intranet or the Internet? If so, what level of remote monitoring and control is configured?

Yes. The ability of remote users to monitor or control is managed through TeamViewer configuration. For example, the remote keyboard input can be limited.

Q: Do you run the scada in conjunction with any third-party application software (Other than MES)?

No.

Management reporting and integration

Q: Does the application include data archiving / historian capabilities with an historical data reporting system?

Yes. Adroit data logging is implemented. Phase 2 of the project will include the implementation of a reporting system.

Q: Is the system integrated with an MES / ERP or other management reporting or control system? (e.g. Baan, SAP, SYSPRO…)

No.

Q: Have any production benchmarking tools been configured as part of the scada system?

No.

Q: Has any asset management functionality been configured in the application (for software assets, control system assets or for plant assets)?

No.

Q: Has any GIS (Geographic Information Systems) functionality been configured in the application?

No.

Q: Are you using tablet PCs or mobile phones to interact with this scada system?

Yes. TeamViewer on tablets for support purposes.

End-user conclusion

Q: What was the predominant feature (or features) that made you decide to purchase this scada product over all others for this application?

Adroit is a user-friendly and easy to understand South African product offering hassle-free service and quick response technical support.

Q: What single feature most impresses you about the product now that it is in operation?

Ease of use.

Q: What impresses you most about the architecture?

The wide range of drivers available.

SI RESPONSES

Project details

Q: Approximately how many man-hours did the scada configuration take?

130 man-hours.

Q: What tools were used to minimise the man-hours taken?

Macro functions in Excel spreadsheets to enable faster tag generation.

Q: What human factors were taken into consideration in the HMI design process?

Mimic pages were designed for operator ease of use. Tabbed page navigation and visual representations of the plant equipment and processes were used to allow rapid visual fault finding. All sequences using SFC (Sequential Function Charts) are shown on the scada to provide operators a clear understanding of process state.

Q: For the graphics development process did you use standard library images, or did you have to draw images from scratch?

Both. Some graphics used available wizards from the vendor; most were quickly developed by our graphic designer to represent the equipment exactly as it is in the plant.

Q: How would you describe the library of graphic images?

The vendor’s library will cover most basic process needs. Ours is not a common application so the graphics are not easily found anywhere.

Q: Did you use any ‘special’ images (e.g. photographs, 3D images, specialised dashboards, etc.)?

Yes. We used 2D representations of temperature distribution over large furnace surfaces to easily identify the development of hot spots.

Q: Did you use any video or multimedia technology in the application?

No.

Q: What alarm management standards or best practices were adopted in configuring the scada system alarms?

We attempted to remove nuisance alarms and provide as much detail quickly to the operator to know what chain of events resulted in the alarm or fault.

Q: What structured processes were followed to determine expected performance under full load, and during abnormal failure conditions?

Most of the stress tests were created accidently during the commissioning phases of the various projects by the plant engineers and technicians.

Q: What are the key physical communication layers and communication protocols employed in the system?

Scada to front end PLC communications is through MELSEC Ethernet Drivers over copper. The majority of the plant communications is with the MCCs and uses DeviceNet over copper.

Q: What levels of redundancy are incorporated in this scada application?

Under normal operation a proxy server provides the plant wide overview. Because the scada machines are linked directly to the front end devices, these can be accessed directly if the plant network fails.

Q: What specific custom code or scada scripts were written for this project?

Customisation to control the 2D graphic temperature representations of the furnace readings.

Project management

Q: What Project Management principles and/or methodologies did you as SI employ to mitigate risk and to ensure the project came out on time and within budget?

Continuous communication with plant engineers and designers before and during the integration of the project.

Security and data protection

Q: How have authentication, authorisation and role management been configured?

Using Microsoft user security, various levels of security and access are easily controlled by user groups that are logged in the machines.

Q: Does the design make provision for a DMZ and firewall segregation of process (scada) network and business networks?

The plant scada network and business network are separate. A proxy server with firewall allows very limited access to certain locations on the scada network.

Q: What intrusion detection has been incorporated on the plant network(s) on which this scada system exists?

None.

Q: What configuration backup and data archive backup methodologies have been adopted?

A weekly scheduled backup is made to a central server using the standard Adroit backup tool.

Q: Did you use any integrated or third-party configuration control system for the scada configuration during the engineering of this application?

No.

SI conclusion

Q: How would you rate the ease of use of the historical reporting system?

If you are knowledgeable of the vendor’s product the setting up of reporting is fairly easy.

Q: What impresses you the most about the engineering / configuration aspects of the product now that it is in operation?

The ease of getting remote viewing set up around the plant to allow various areas to see only the relevant scada sections.

Q: What impresses you most about the architecture?

The Adroit architecture with Adroit servers located at the plant where the PLCs are results in efficient network bandwidth usage because clients connect to the proxy server, which only fetches the data that needs to be displayed on the Adroit graphics.

VENDOR RESPONSES

Product

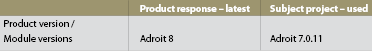

See Table 1.

Q: Vendor comments on product / modules?

Adroit 8, with a launch date of May 2013, is the latest Adroit SCADA release.

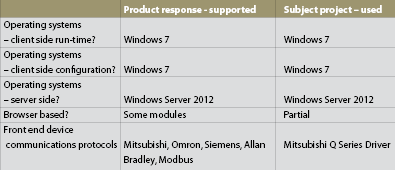

Operating systems / VMware

See Table 2.

Q: Vendor comments on operating systems

Microsoft .NET platform, Microsoft ClickOnce and XAML importing supported.

Licensing, maintenance and support model

Q: What sort of licensing agreement options are offered?

The Adroit SCADA licence comprises core modules. Additional modules such as Alarm Management, OEE and MaxDemand are available.

Q: Are licences sold outright or subject to periodic (e.g. annual) renewal?

Licence is a once-off purchase for a version.

Q: What upgrade agreements are offered?

Version updates are offered free.

Q: What after-sales offerings iro support and maintenance are available, and which technologies are used to deliver them?

Telephonic and e-mail technical support is offered as a free unlimited service. Adroit can assist with onsite support if required at a support rate.

Technology incorporated

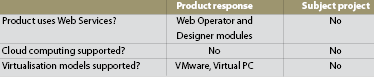

See Table 3.

Q: What new technology has been introduced into the product in the last 12 months?

A tablet-friendly user interface, see Adroit 8 (Smart SCADA) features list for full details.

Management reporting and integration

Q: What native historical data reporting options are available?

Adroit offers OLE DB connectivity which enable users to report on data in the scada interface. Adroit also has easy integration with Microsoft Excel and HTML for reporting capabilities.

Q: What product specific interfaces does the product have iro well-known MES packages?

Adroit OEE, Alarm Management and Auditing data logging into SQL database allows for easy integration with any MES package that supports OLE DB connectivity.

PLC configuration and programming

Q: What capabilities does the scada offer in terms of generation and/or management of PLC configuration files or PLC application code?

No PLC application files are generated. Adroit offers exporting of configuration to Microsoft Excel.

Security and data protection

Q: What authentication, authorisation and role management models are available for the runtime environment?

Windows user management services.

Unique selling proposition (USP)

Q: List the top five feature/benefit pairs that contribute to this product’s USP.

1. Simple design and operator interface – Quicker, easier engineering lowering development costs.

2. Easy centralised configuration – engineer at one point and distribute across the network.

3. Unlimited alarming and trending – optimise and understand your process easier.

4. Web operator interface – no client application installation necessary.

5. Online system development – no downtime needed for scada project development.

| Tel: | +27 11 658 8100 |

| Fax: | +27 11 658 8101 |

| Email: | [email protected] |

| www: | www.adroit.co.za |

| Articles: | More information and articles about Adroit Technologies |

© Technews Publishing (Pty) Ltd | All Rights Reserved