In many locations, environmental regulations require ‘smokeless flares’ to minimise hazardous emissions. To satisfy these requirements steam injection systems are typically used to add oxygen to the flame in order to help complete the combustion process and to eliminate the smoking conditions.

Many flare stacks use a simple manual procedure to inject steam into the flare to complete the combustion process. However, due to the variability of the burn off gas composition, density, and feed rates, this manual control process can be ineffective, costly and noisy. To maintain a smokeless flare with manual control, steam must be run continuously and at excessive rates in order to properly compensate for peak emission requirements. If there is a flare shutdown, it is also not unusual to continue steam injection to protect against future emissions after start-up. Consequently, this inefficient use of steam can cost millions of dollars annually per flare stack.

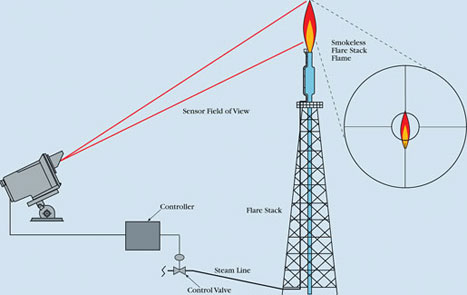

To more effectively manage hazardous emissions and energy costs, the Flare Monitor system from Williamson Corporation continuously monitors the status of flare combustion and instantly regulates the flow of steam to suppress smoking conditions. This ensures smokeless flare burning while helping to cut energy costs through a more efficient use of steam.

This non-contact infrared sensor sees the opacity of the dirty smoky flames, while it sees through the hot clean flames. Thus, the system is able to provide continuous monitoring of the flare emissions by measuring the flame opacity and only calling for steam when smoke is being generated. This results in a more efficient and reliable method of maintaining an environmentally clean and smokeless flare operation. In addition to controlling the steam valve, the system includes an adjustable alarm to signal the frequency, time and duration of any environmental emission problems.

The Flare Eye system is a non-contact infrared sensor that is specifically designed to monitor and control smokeless flare stacks. This system is installed at ground level (at a distance of 100–1000 m from the flare) to provide easy access for installation, operation and maintenance. Specific features include:

* A rugged mounting base, through the lens sighting, and an adjustable swivel bracket that makes it easy to install and align the sensor.

* A continuous monitoring and control capability that enables the system to automatically inject steam into a smoky flame without any operator intervention.

* A modular design and rugged NEMA4 (IP65) enclosure (NEMA7 optional) that provides protection from the environment and virtually maintenance-free operation.

To provide accurate and reliable monitoring of smoking flame conditions, the Flare Eye system uses a special narrow band infrared filter to detect smoke particulate in the flames. The built-in PID controller then provides a 4–20 mA output signal to adjust the steam valve based on the presence of smoke in the flame. This ensures the smokeless operation of the flare stack.

For more information contact Andy Brown, Temperature Controls, +27 (0)11 791 6000, [email protected], www.tempcon.co.za

| Tel: | +27 11 791 6000 |

| Email: | [email protected] |

| www: | www.tempcon.co.za |

| Articles: | More information and articles about Temperature Controls |

© Technews Publishing (Pty) Ltd | All Rights Reserved