Major threats to safety in the mining industry include toxic gases, fire and dust. The South African mining sector can improve the safety of workers by choosing robust, reliable equipment to monitor environments, detect hazardous conditions and utilise the information to act proactively. Challenges include early detection of fires, monitoring of explosive atmospheres and the optimising of ventilation system performance.

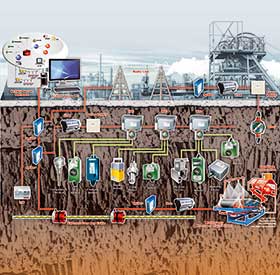

Underground monitoring with the Sperosens SL2010 system

The SL2010 telemetry system provides underground data collection and communication from the mine’s fibre-optic backbone to the control centre where data-logging, alarming, displaying and reporting takes place. Various sensors can be incorporated to monitor conditions and the information can then be used by the safety and health officials to ensure all conditions are within acceptable limits. The network is based on LonWorks technology and implemented as a free topology, which is custom-configurable and expandable based on a specific mine’s requirements. The system captures, stores and displays data, with information also available by remote web access.

Air temperature and humidity are important parameters to manage heat stress, and are monitored continuously, especially at the mining face where large concentrations of workers are present, and ventilation is sometimes stressed to the limit.

Air velocity is measured at strategic points to ascertain that the ventilation distribution is functioning normally. Status of ventilation doors (open/close) are also monitored to make sure that they are not short-circuiting the ventilation flow and hence cutting off the supply deeper into the mine, which may cause toxic gas levels and temperatures to rise in areas with high concentrations of workers.

Continuous dust monitoring is also becoming increasingly important. Respirable dust (i.e. silica dust particles <7 μm) can cause silicosis, which most often only shows up in workers after extended exposure, and normally many years later.

The present SA mining regulations limit worker exposure on an 8-hour TWA basis to 0,05 mg/m3 respirable silica dust. This is presently done by control measurements using sampling and analysis, alongside expensive continuous measuring instruments that measure total dust concentrations. Technology is still some way from yielding an affordable, continuous monitoring instrument that can be located in a workplace and which measures to this standard.

Fire down below

The single biggest threat to human life in underground mines is fire. Due to the artificial environment with limited fresh air supply, air quality is very quickly threatened by toxic gases and fumes. Carbon monoxide gas (CO) and smoke are by far the biggest threats during an underground fire. Therefore, it is imperative that early detection of fires is assured.

The Sperosens telemetry system is extensively used for fire detection. For this reason, CO gas sensors and smoke sensors are placed at strategic positions along the entire tunnel network.

CO gas sensors have a full scale range of 200 ppm. Smoke sensors are custom-designed using radioactive ionisation, the only sustainable technology in the hot, humid and dusty environment. Other techniques, such as infrared, are prone to contamination of the optical surfaces. Special software alarming algorithms are deployed in the control centre computers to distinguish between a real fire and spurious signals from blasting or passing vehicles.

During an underground fire, the proto teams will also install sensors on the telemetry system to monitor the progress of a fire in the control centre. High concentration CO sensors (up to 100 000 ppm), CO2 sensors and temperature sensors are deployed at strategic positions. By monitoring the temperature and content of the fire effluent, the ventilation engineer can judge if the firefighting techniques are succeeding, and if the fire is being brought under control.

Since fires can sometimes take months to recede, it is often economically unaffordable to close down a mine until the fire is completely extinguished. Hence operations must restart as soon as it is safe. Again, the telemetry system is used to ensure that no ‘leakage’ of dangerous effluent gets into the fresh air supply.

Methane risks in coal mines

The risk of methane explosions in coal mines is usually located around the areas where virgin coal is exposed (i.e. the working face), as well as areas where there is weak ventilation.

Methane monitoring sensors are deployed on mechanical mining machines to monitor the methane content in the air coming from the cutting head. When methane levels exceed 1% concentration, the machine is automatically immobilised, and can only restart when the threat has been removed.

Telemetry systems are also deployed to measure the air quality entering and leaving the working section of a coal mine. Air flow is measured at the intake to determine that enough fresh air is entering, while air flow, CO and methane are measured at the exit side.

Optimising the running cost of the ventilation system

The running cost of deep mine ventilation systems is one of the largest operating expenses, due to the cost of electricity. Projects are underway whereby the power to the ventilation fans is reduced (i.e. air speed is reduced) and cooling plant output air temperature is allowed to increase, thus saving electricity.

The Sperosens telemetry system is used to monitor temperature, humidity, airflow and gas levels at critical positions. The data is then fed into a complex system that controls fan speeds and increases or reduces cooling plant temperatures. This technology is continually progressing to help address the dangers of underground mining, and the complexity of the harsh environments in which the monitoring systems must operate.

For more information contact Marihette Hattingh, Sperosens, +27 (0)12 665 0317, [email protected], www.spero.co.za

© Technews Publishing (Pty) Ltd | All Rights Reserved