Whether you work in an oil and gas refinery, a chemical plant, or a petrochemical facility, having an unplanned shutdown can result in a long chain of negative effects. It reduces throughput, requires expensive maintenance and repair, impacts margins and can even cause safety and environmental incidents.

Unmonitored essential assets are one of the main reasons of production slowdown or shutdown. By ‘essential assets’, we mean those less critical but still essential whose outage can cause significant disturbance in production. These are sometimes referred to as ‘second-tier’ assets, and may not have been considered critical enough to be monitored using advanced systems. Examples include air cooled heat exchangers (fin fans), blowers, cooling towers, non-critical compressors, heat exchangers, pipes, vessels and pumps.

The good news is that innovations in process automation, particularly in the field of wireless, have changed the game in the refining, chemical, and petrochemical industries. Emerson Process Management, one of the pioneers in industrial wireless, has made automated wireless monitoring available and more affordable. With affordable monitoring, plant operators can take advantage of applications to cover all their key assets and consequently avoid shutdowns, maintenance costs, and reliability issues.

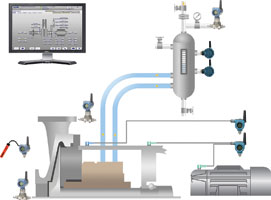

Last year, Emerson launched the industry’s first-of-its-kind family of integrated wireless application solutions for essential asset monitoring. Pre-engineered and scalable, these solutions allow users to choose the number and type of applications to monitor faults or threats in a plant. The tailored, integrated solution transmits information from the wireless field devices to dedicated operator graphics and maintenance screens as well as host systems and data applications that give personnel a clear picture of what is happening in the plant.

Pump health

Typical oil and gas plants have hundreds of pumps in use, only a small percentage of which are being constantly monitored – those that operators deem as most critical or have high cost of repair. The rest of the pumps are checked manually, which often opens a window for risks. Most of the time, manual checks do not detect mechanical wear that can result in failure of seals, bearings and other internals. It also does not easily identify misalignment or imbalanced installation of pumps.

An Emerson Pump Health Monitoring solution allows users continuously to watch conditions that they are most concerned about. These conditions include cavitation, excessive temperature, vibration, process leakage, seal spot level and differential pressure imbalance. A user-friendly asset management interface gives personnel a quick view of all the conditions and issues alerts for situations that require attention. And because it is wireless, the solution can be deployed quickly without expensive and time-consuming engineering, trenching, and cabling activities.

Cooling towers

Industrial cooling towers are used to remove heat from equipment and cool heated products and raw materials. These are used in power plants, petroleum refineries, petrochemical plants, food processing plants and other industrial facilities.

Production slowdowns can happen because of failures in cooling towers. These usually spring from issues like cooling inefficiency, scaling and corrosion, excessive and insufficient makeup and blowdown flow, pumps and fans faults and high or low cycles of concentration.

To address these challenges, a combination of wireless instruments can be installed on the towers to spot potential bearing, lubrication or alignment issues. The information from these instruments is seen in clear, graphical displays to help personnel to recognise, prioritise and troubleshoot problems, manage energy consumption efficiently and obtain cost savings.

Air cooled heat exchangers

Failures in air cooled heat exchangers or fin fans can limit cooling and slow down production. Root causes of failure include fan vibration, bearing wear, dust, oil and corrosion on tube fins or freezing ambient temperatures. These issues, when unresolved, develop into bigger problems like poor cooling, relief valve lift and flaring. Environmental incidents from flaring may lead to expensive fines and rebuilding costs.

Emerson’s wireless monitoring solution for fin fans oversees and diagnoses the full range of failure modes to alert personnel of deteriorating equipment health. This allows personnel to adjust their operation with the fin fans’ cooling capacity and to take fast corrective maintenance action.

SABIC Olefins plant

Right now, there are over 17 000 Emerson wireless networks operating around the world. One of them is at the SABIC Olefins plant in Teesside, which has delivered proven results in detecting potential pump problems and avoiding maintenance costs.

SABIC Teesside previously collected and analysed vibration data for these pumps manually, but potential problems could occur between readings. This led to higher maintenance costs and reduced plant availability, which was affecting overall production.

Emerson’s wireless vibration monitoring system has detected a number of problems that could have resulted in equipment failure, including a chipped tooth on a gear and an impending bearing failure. Identifying and rectifying potential problems earlier helps minimise pump failures and maintenance costs.

In addition to measuring overall vibration and temperature, the CSI 9420 wireless vibration transmitter includes PeakVue technology, which detects faults that cause impacting, friction and fatigue, particularly in gearbox and rolling element bearings. The monitoring system takes basic readings every 60 seconds and an in-depth, full spectrum analysis once every day. By tracking rising vibration levels, SABIC Teesside can detect developing faults and improve maintenance scheduling.

Going wireless

Deploying an effective essential asset monitoring programme is easy by consulting with an Emerson Engineer. It all starts with a casual discussion to help users learn more about the technologies and to identify asset monitoring improvements. After this, they can choose which steps to take to begin. An Emerson Engineer will be able to identify where automation would have the most significant benefits and what risk exposure should be reduced in a plant. Support will be available from the earliest planning stages, up to project justification, and right through installation, start-up and beyond.

For more information contact Ron Raubenheimer, Emerson Process Management, +27 (0)11 451 3700, [email protected], www.emersonprocess.com

| Tel: | +27 11 451 3700 |

| Fax: | +27 11 451 3800 |

| Email: | [email protected] |

| www: | www.emerson.com |

| Articles: | More information and articles about Emerson Automation Solutions |

© Technews Publishing (Pty) Ltd | All Rights Reserved