Advances in technology and ease of installation have led to the Coriolis mass flowmeter finding wide acceptance in industrial flow measurement. The impressive zero point stability of today’s instrument – ensured by means of balancing technology – infers high accuracy for a wide range of flow rates in a broad applicable spectrum. Balanced system instruments are also far simpler to install.

Field instrumentation and process control specialist Endress+Hauser comes one step closer to the ideal Coriolis meter - notably, a simple straight pipe - with the introduction of the Promass I Coriolis mass flowmeter. By virtue of its single-tube balanced system, this instrument has made the Coriolis measuring technique available to those parts of the process control line that demand high 'cleanability', clogging protection and a simple installation straight-through tube (full bore). In understanding the development of the Promass I, it is necessary to examine in brief the annals of Coriolis technology.

For Coriolis mass flowmeters, the key to good zero point stability lies in the decoupling of the measuring element from the process environment. A flow signal is derived from the phase shift of the sensors at an oscillating measuring tube and a poor decoupling system causes the connected pipelines to vibrate - effectively 'confusing' the vibration sensors of the measuring tube. External vibrations - such as from pumps or valves - are not critical because they fail to correlate with tube vibration and will thus be filtered out in the transmitter electronic. However, the oscillation of the instrument itself causes systematic zero point errors because these disturbances mirror the frequency of the measuring tube vibration.

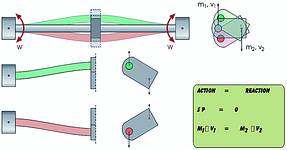

In overcoming this, early Coriolis flowmeters had to be mounted on solid ground to control their strong vibration. To achieve excellent zero point stability without such elaborate installation, manufacturers began experimenting with oscillation compensation by means of flow-splitting balancing mechanisms. Splitting flow into two tubes oscillating in counterphase dampens the vibration of each tube. This internal balance eliminates pressure on the housing and on the process connections - the most essential requirement for a stable zero point.

Although this design went a long way in reviving the approval of Coriolis flowmeters, a demand still existed for single tube meters - particularly in applications with high clogging activity. Instruments without flow splitters remained attractive based on their cleaning performance. Reverting to a single tube meter signified a re-acquaintance with the vibration problems of the past, as the only balancing systems available at that time related to double tube designs. This changed in 1987 when Endress+Hauser developed and patented the TMB system - a balanced system for a single straight tube, operational within a much wider density range than with previous counter transducers.

Endress+Hauser incorporated the TMB system into its Promass I range, combining the advantages of a high-accuracy double tube with the ease of installation of a single straight tube. Key to the Promass I design is a pendulum attached to the measuring tube that oscillates counterphase to the tube, compensating for the momentum of the measuring tube. Moreover, the pendulum introduces a torsion mode into the oscillating system. Using a support structure with a centre of gravity out of the tube axis, the torsion of the measuring tube is transformed into a lateral motion. This motion alone compensates for the residual momentum of the measuring tube. With the torsion mode, virtually perfect balance is maintained over a wide density range.

For elegance in operational design, the measuring tube and all process connections are welded and are constructed of the same material (titanium) throughout. Boasting no internal gaskets and complete cleanability, the instrument is fully certified according to EHEDG specifications. A wide range of process connections includes full bore straight-through flange versions to minimise pressure loss and obtain careful handling of the medium, as well as hygienic connections for food and beverage applications.

The Promass I has proven itself in several industry sectors, such as in high temperature, abrasive media and low flow-rate applications that include food production, and in high viscosity applications such as rubber manufacture. With installation requirements that amount to practically zero, tight, crude installations present little problems for the Promass I. In all documented cases, uncertainty remains within the instrument's specification and within flow speed range.

The functionality of Coriolis mass flowmeters extends into adequate density measurement - because the resonance frequency of the tubes' vibration gives exact information about density. Leaving little doubt that Coriolis meters offer the highest accuracy in flow measurement, for a wide range of flow rates, the Promass I looks set to redefine flow monitoring performance and ease of implementation in the applications of today and tomorrow.

Endress+Hauser

(011) 262 8000

© Technews Publishing (Pty) Ltd | All Rights Reserved