End-user details

Company: Swaziland Water Services Corporation

Phone: (00268) 7802 8124

SI details

Name: Craig Webber

Designation: Systems Technician

Company: Vanguard Projects

Phone: +27 (0)13 752 3339

E-mail: engineering@vangardprojects.co.za

Product details

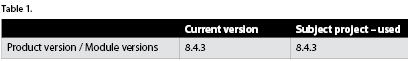

Product name and version: Adroit 8.4.3

Vendor: Adroit Technologies

Phone: +27 (0)11 658 8100

E-mail: info@adroit.co.za

URL: www.adroit.co.za

Application details

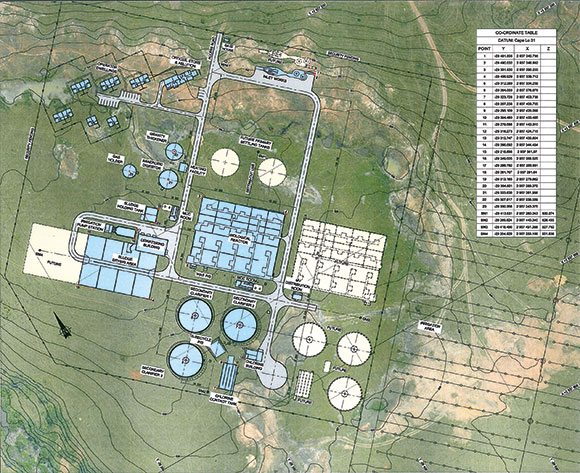

Location: Matspapha, Swaziland

Industry: Wastewater

Project start date: 2016-03

Project end date: 2017-03

Application: Wastewater treatment plant

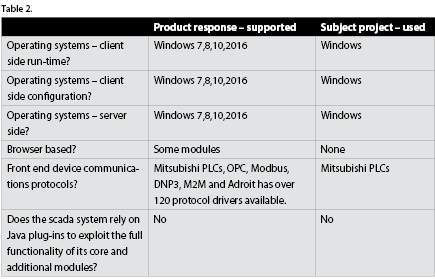

Server OS: Windows 7,8,10,2016

Client OS: Windows 7,8,10,2016

Application statistics

Tag count: 1500

Updates per day: 86 400

Disk space for one day’s updates: 8 MB

Physical I/O count: I/O: 500 Analog: 40

Front ends: 3 x Mitsubishi PLCs q series 25 x F840 VSD

Licences: Adroit 8.4.3

Scada configuration man-hours: 20 hours

End–user responses

General

Q: Briefly describe the application, including information on any pre-existing control system.

System was installed for a new wastewater treatment plant to monitor and control it.

Q: What was the primary motivation for the project?

New system to replace a redundant system.

Q: What were the main goals established for the project?

To install a new scada system capable of monitoring and controlling the pump stations and reacting to alarms.

Q: In the procurement decision-making process what were the primary considerations that influenced the product selection?

Local support from vendor, and cost of the product.

Q: What project management principles and/or methodologies did you employ as end-user to mitigate risk, ensuring the project came out on time and within budget?

Internal project management procedures.

Licensing, maintenance and support

Q: What upgrade agreements are in place for this application?

Standard Adroit updates.

Q: How is after-sales support handled on this application?

One year maintenance from the system integrator, Vangard Projects, coupled with free telephonic, email and remote desktop support during office hours from Adroit Technologies.

Q: Do you have a documented process in place to manage, test and install OS and scada system software patches?

No process for OS but there is a documented process for the Adroit update mechanism.

Integration, reporting and archiving

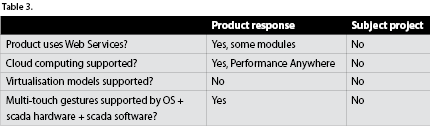

Q: Is the scada system integrated onto an intranet or the Internet?

No, it is a standalone system.

Q: Is the system integrated with an MES/ERP or other management reporting or control system?

No.

Q: Has any GIS (Geographic Information Systems) functionality been configured in the application?

No.

Q: Has any asset management functionality been configured in the application?

No.

Q: Does the application include data archiving/historian capabilities with an historical data reporting system?

Yes, standard Adroit data logging.

Maintenance, reliability and asset optimisation

Q: What maintenance, reliability, asset optimisation or continuous improvement criteria were included in the user requirements specification for this project?

None.

Mobile device support

Q: Do you allow users to interface with the scada system via their own personal smart devices? (BYOD)

No.

End-user conclusion

Q: What was the predominant feature (or features) that made you decide to purchase this scada product over all others for this application?

This scada is a world-class product locally developed and supported.

Q: What was the most significant change that you implemented in scada engineering practice/technology in this project?

Standardisation on graphic and I/O objects.

Q: What single operational feature most impresses you about the product now that it is in operation?

The standard MAPS UIs for motors and VSDs is very interactive along with standard objects, standard alarming and standard data logging. Adroit objects have a filtered alarm page and each Adroit object has its own standard alarming and data logging. I/O scan addresses are automatically created.

Q: What impresses you most about the architecture?

The ease at which it scales, coupled with the standard naming convention, standard logging and standard alarming and scanning.

SI Responses

Project details

Q: What tools were used to minimise the man-hours taken?

MAPS plant wizard.

Q: What human factors were taken into consideration as principles or development standards in the HMI design process?

Internal HMI standards.

Q: For the graphics development process did you use standard library images, or did you have to draw images from scratch?

Mostly standard Adroit libraries.

Q: How would you describe the library of graphic images?

Comprehensive.

Q: Did you use any ‘special’ images?

No.

Q: What alarm management standards or best practices were adopted inconfiguring the scada system alarms?

Adroit standard alarm management, which filters alarms according to the equipment type and can be viewed by plant sections.

Q: What are the key physical communication layers and communication protocols employed in the system?

PLC to VSD: Modbus and PLC to scada: fibre ring network.

Q: What is the network speed and communications medium of the slowest link in this project’s scada network?

100 MB/s over Ethernet.

Q: What is the network speed and communications medium of the fastest linkin this project’s scada network?

1 GB/s over fibre.

Q: What levels of redundancy are incorpor-ated in this scada application?

Ring topology on the fibre network.

Q: Was any specific custom code or scada scripting written for this project?

No.

Maintenance, reliability and asset optimisation

Q: What steps were taken to address maintenance, reliability, asset optimisation and/or continuous improvement aspects relating to this system?

Adroit offers alarming and auditing on an equipment level.

Security and data protection

Q: How have authentication, authorisation and role management been configured?

No.

Q: Does the design make provision for a DMZ and firewall segregation of process (scada) network and business networks (LAN, WAN, GAN, Internet, etc.)?

No.

Q: What intrusion detection has been incorporated on the plant network(s) on which this scada system exists?

None. It is an isolated network with standard windows security.

Q: What configuration backup and data archive backup methodologies have been adopted?

None.

SI conclusion

Q: What impresses you the most about the engineering/configuration aspects of the product now that it is in operation?

Adroit reduced the engineering time significantly through equipment standards, standard equipment units, and faceplates. Graphic objects are created automatically and alarming, data logging and I/O creation and scanning is also done automatically by Adroit.

Q: What impresses you most about the architecture?

Easy to scale and modify the architecture.

Vendor responses

Product

Q: Vendor comments on product / modules?

Adroit 8.4.3 offers performance enhancements and Windows 10 compatibility.

Operating systems/VMware

Licensing, maintenance and support model

Q: What sort of licensing agreement options are offered?

Licensing is scanned I/O based – all internal logs are free, including alarms and historical log tags with databases. Base licence comprises of core modules. This however differs for the size of system you have.

Additional value adding modules can be purchased separately.

Q: Are licences sold outright or subject to periodic (e.g. annual) renewal?

Outright with technology support/maintenance agreement optional. Licence is a once-off purchase per major version release. Small version updates are free. Licence requires annual renewal.

Q: What upgrade agreements are offered?

Group wide support and sales arrangements are available along with maintenance agreements. Adroit minor version and patch upgrades are free.

Q: What after-sales offerings iro support and maintenance are available, and which technologies are used to deliver them?

Site auditing and onsite support can be offered as an annual agreement. Telephonic and remote desktop support is offered free during office hours.

Q: Do you have a documented process in place to manage and test OS patches and to release scada system software patches?

Yes, internally driven. The testing department has a procedure to test Adroit products against latest Windows releases and upgrades. Adroit has an audit procedure document.

Technology incorporated

Q: What new technology has been introduced into the product in the last 12 months?

Performance Anywhere and the Adroit health monitor.

Integration and reporting

Q: What generic and/or product specific interfaces does the product have iro well-known MES packages?

OPC UA, OPC, .NET v4.0, VB v6.0, Excel, SQL Server and MS Reporting Services – the Adroit Smart Intelligence product is built on MS Business Intelligence technologies.

Q: What native historical data reporting options are available?

Our trends support export to Excel, PDF, JPG and CSV formats. Adroit has its standard flat file data logging that is used for trending and charts and can also log to multiple different databases Microsoft SQL, Oracle, etc. Adroit Scada interface can then also be used to create simple data queries to report data in the interface. Microsoft Reporting Services can then also be hosted in the user interface via the url tool. Adroit offers free report suite with Adroit audit reports.

Maintenance, reliability and asset optimisation

Q: What maintenance, reliability, asset optimisation and/or continuous improvement related modules or capabilities does the product incorporate?

SNMP capability – possible to monitor LAN performance and IT infrastructure. All software changes and processes are logged to Microsoft Windows Events with a unique ID for Adroit. Adroit can also log this data to SQL if need be. Adroit offers Report Suite which comes with free audit reports for the system.

PLC configuration and programming

Q: What capabilities does the scada offer in terms of generation and/or management of PLC configuration files or PLC application code?

Adroit supports object-based generation of function blocks and scada objects in Mitsubishi Electric range of PLCs. I/O and PLC generated by Adroit.

Security and data protection

Q: What authentication, authorisation and role management models are available for the runtime environment?

MS security and data and standard windows security.

Unique selling proposition (USP)

Q: List the top five feature/benefit pairs that contribute to this product’s USP.

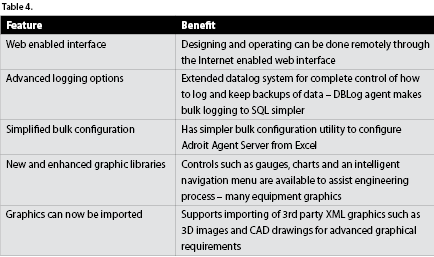

To view the unabridged version of this scada review, please visit http://instrumentation.co.za/+J2250

| Tel: | +27 11 658 8100 |

| Fax: | +27 11 658 8101 |

| Email: | info@adroit.co.za |

| www: | www.adroit.co.za |

| Articles: | More information and articles about Adroit Technologies |

© Technews Publishing (Pty) Ltd | All Rights Reserved