LSIS is committed to the future of smart energy. With its tradition of going the extra mile when designing and building equipment, this Korean manufacturer of automation and drive systems is a force to be contended with especially when it comes to the medium voltage drives offering.

The LSMV-M1000 is worth every penny from the innovative design and packaging to the energy savings on implementation. It also boasts some key features that make it one of the market leaders in this sector.

Starting with an all-in-one system, the M1000 caters for 3,3 kV-13,8 kV with combinations of output voltage available. For example, a 6,6 kV motor can be run off a 13,8 kV supply with LSIS flexible input/output voltage ranges.

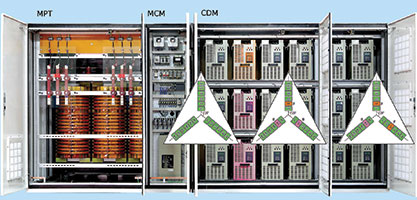

The M1000 has a built-in ‘multi-winding phase-shift’ transformer (36 pulse/18 winding) with taps to accommodate variations in input voltage. This also helps to eliminate the need for chokes and filters and by extension allows for greater distances between motors and drives. The order options for the transformers are offered as either built into the drive or standalone air or oil cooled variations.

The ‘Master Control Module’ manages the multi-level PWM output voltage, the power cells and fibre optic communication, using the LSIS-XGi plc for control, the LSIS-XP80 HMI and the LSLV-iG5A inverters for the cooling system control, which are all available off the shelf in South Africa.

The ‘Cell Drive Module’ utilises six low voltage single-phase drives connected in series per phase. This generates multilevel 3-phase output voltage. The configuration is known as the cascaded H-bridge multi-level drive. This results in capabilities such as flying start, ride through of up to 5 cycles, anti-current hunt algorithms and sensorless vector torque control to mention a few.

Additionally, the transformers are shielded from the MCM and CDM thus eliminating the effects of power spikes or lightning strikes from either interrupting or destroying these two critical systems.

Each cell has its own IGBT and control card thus allowing for cell protection and bypass. For example should U2-phase cell fail its control card bypasses it and the control system automatically bypasses the corresponding V2 and W2 cells thus balancing the output phases. Shutdown time is cut down to a minimum as the offending cell is simply replaced from the front by loosening its bus connections behind it, pulling the defective cell out and inserting the new cell in its place, then reconnecting its bus and powering the system up.

The LSMV-M1000 is also aesthetically pleasing and adds an air of professionalism and dignity to the installation. Thus when it comes to weighing up the options this one stop drive is a definite option in its class, a credit to the LSIS brand and an asset to any installation.

| Tel: | +27 21 914 9030 |

| Email: | info@anadigi.co.za |

| www: | www.anadigi.co.za |

| Articles: | More information and articles about Ana-Digi Systems |

© Technews Publishing (Pty) Ltd | All Rights Reserved