End-user details

Name: Adrian Viljoen

Designation: Member

Company: Prentec

Phone: +27 (0)11 976 5234

E-mail: [email protected]

URL: www.adroit.co.za

Application details

Location: Boekenhouthoek, Mpumalanga, South Africa

Industry: Water

Project start date: 2015-10

Project end date: 2016-03

Application: Community based off-grid water treatment plant

Server OS: Windows 7

Client OS: Windows 7

Application statistics

Tag count: 980 across 7 sites

Updates per day: Approx. 432 000

Disk space for one day’s updates: 5 MB

Physical I/O count: 1200 * Digital; 800 * Analog; 40 * Expression; 40 * Script

Front ends: Mitsubishi FX5 PLCs with ME-RTUs

Licences: 750 I/O Adroit with the built-in DNP3 driver to communicate to the Mitsubishi Electric ME-RTU using GPRS.

Scada configuration man-hours: Interface design 40 hrs. Database design 40 hrs.

END-USER RESPONSES

General

Q: Briefly describe the application including information on any pre-existing control system.

The solution is an off-grid mini water treatment plant. Driven by solar the Aquastation system can use any water source (borehole/river) and produces potable water. The process uses a Mitsubishi membrane/Mitsubishi Electric FX5 PLC, a Mitsubishi Electric D720 VSD and Mitsubishi Electric ME-RTU as well as Adroit SCADA. It treats, doses, backwashes, all fully automatically and is driven from PV panels on top of the unit.

Q: What was the primary motivation for the project?

To provide potable water to the Boekenhouthoek community.

Q: What were the main goals established for the project?

To supply 7,5 litres minimum per day per person where the source is located more than 1 km away or that the round trip to fetch the water is more than 30 minutes based on the World Health Organization’s guideline for basic needs.

Q: In the procurement decision-making process what were the primary considerations that influenced the product selection?

Machine-2-machine remote monitoring as well as the centralised hosted scada system.

Q: What project management principles and/or methodologies did you employ as end-user to mitigate risk, ensuring the project came out on time and within budget?

Internal Prentec project management was used.

Licensing, maintenance and support

Q: What upgrade agreements are in place for this application?

Annual maintenance and technology agreements.

Q: How is after-sales support handled on this application?

Firstly through the system integrator LBA and secondly through Adroit Technologies’ support team using Teamviewer.

Q: Do you have a documented process in place to manage, test and install OS and scada system software patches?

This is handled through the Adroit update mechanism.

Integration, reporting and archiving

Q: Is the scada system integrated onto an intranet or the Internet?

Both. Operator is Internet enabled and allows the client, Prentec or LBA to logon. Security rights determine what functionality is available to which party. Adroit hosted standard operators and login on Internet.

Q: Is the system integrated with an MES/ERP or other management reporting or control system?

No.

Q: Has any GIS (Geographic Information Systems) functionality been configured in the application?

Yes – through the standard GIS functionality in Adroit SCADA. Sites are displayed geographically on a map that shows the status of each site.

Q: Has any asset management functionality been configured in the application?

All running times and performance of plant assets are monitored in the scada.

Q: Does the application include data archiving/historian capabilities with an historical data reporting system?

Yes. All plant history is used to improve the efficiency and operation.

Maintenance, reliability and asset optimisation

Q: What maintenance, reliability, asset optimisation or continuous improvement criteria were included in the user requirements specification for this project?

Off-grid continuous optimisation of solar operation including storage and real-time operation directly from solar power.

Mobile device support

Q: Do you allow users to interface with the scada system via their own personal smart devices? (BYOD)

Yes. This is possible with Adroit, however it has not been configured.

End-user conclusion

Q: What was the predominant feature (or features) that made you decide to purchase this scada product over all others for this application?

This scada is a world-class product locally developed and supported. The pricing was good and the provider’s teams have excellent knowledge and expertise within the industry and with the product and its capabilities. The provider is trusted as we have used them a number of times. The technology of the product is of great quality and value and the provider had an understanding of the challenges of this project and environment.

Q: What was the most significant change that you implemented in scada engineering practice/technology in this project?

Using the Mitsubishi Electric ME-RTU system with DNP3, which required using Open VPN to facilitate communication over GPRS. In addition, the control technology used to optimise the use of the implementation of the pump control system with the Mitsubishi Electric VSD.

Q: What single operational feature most impresses you about the product now that it is in operation?

The ability to do online program changes for the PLC, VSD and scada over GPRS, which reduces the time and cost of having to make these changes on site, being able to manage the system remotely is of great value.

Q: What impresses you most about the architecture?

The ability to host in the cloud and access from anywhere, as well as online program changing.

SI RESPONSES

Project details

Q: What tools were used to minimise the man-hours taken?

Bulk Excel Configuration tool. Wizards and templates were also used and CSV import/export for scanning, data logs and the creation of all tags.

Q: What human factors were taken into consideration as principles or development standards in the HMI design process?

Realistic graphical representation of the site, coupled with standard navigation format.

Q: For the graphics development process did you use standard library images, or did you have to draw images from scratch?

Standard library together with customised graphics.

Q: How would you describe the library of graphic images?

Simple, yet powerful.

Q: Did you use any ‘special’ images?

Yes, 3D images.

Q: What alarm management standards or best practices were adopted in configuring the scada system alarms?

Standard Adroit Best Practices Alarming.

Q: What are the key physical communication layers and communication protocols employed in the system?

Public IP Internet connection to PLC via GSM network.

Q: What is the network speed and communications medium of the slowest

link in this project’s scada network?

Normal GSM network speed. Depends on physical elements.

Q: What is the network speed and communications medium of the fastest link in this project’s scada network?

50 Kbps – GSM network.

Q: What levels of redundancy are incorporated in this scada application?

Stand-alone system, but PLC driver code has history buffer memory, so when scada link is back on again after a disconnect, all data is polled from PLC history buffer.

Q: Was any specific custom code or scada scripting written for this project?

Yes, history buffering and automated process control. User input minimum. Process control and initial setup values calculated in VBScript, kWh counting, flow calculations and dosing calculations done in VBScript. Some operator information determined through VBScript to allow the operator more data without putting too much traffic on the GSM network and to use fewer tags.

Maintenance, reliability and asset optimisation

Q: What steps were taken to address maintenance, reliability, asset optimisation and/or continuous improvement aspects relating to this system?

Scada control was developed to monitor and control the remote site. This monitoring is done on a 24 hour, 7 days a week basis to ensure that the product delivered is always of the highest quality.

Security and data protection

Q: How have authentication, authorisation and role management been configured?

Standard Windows OS Security as user interaction will be minimal.

Q: Does the design make provision for a DMZ and firewall segregation of process (scada) network and business networks (LAN, WAN, GAN, Internet, etc.)?

Yes, the solution required a Fixed Public IP to enable communication. This fixed IP could either be a PC connected directly onto the Internet or a modem/router to a company network. However, port forwarding and firewalls had to be configured correctly. This static public IP is required as the ME-RTU solution uses the Open VPN protocol which requires a static IP address.

Q: What intrusion detection has been incorporated on the plant network(s) on which this scada system exists?

An input on the PLC is for intrusion detection. When this is triggered, it gets sent to the PLC after 30 seconds if not acknowledged by a key in a digital lock.

Q: What configuration backup and data archive backup methodologies have been adopted?

Historical data logging using the Adroit logging agents. These are exported as .CSVS when analysis is required.

SI conclusion

Q: What impresses you the most about the engineering/configuration aspects of the product now that it is in operation?

The datascope that Adroit has written – if you know where to look, this system gives a large amount of information regarding the scanning, updating, etc., of configured tags. When using a system like this one (GSM, connection in a rural area), it is critical to know that your information is being communicated correctly across the protocols used. The ease of configuring additional client connections to the server is another notable feature.

Q: What impresses you most about the architecture?

The communication architecture that is used is very robust. The communication speed is also at times impressive. One key feature is the fact that you can access the PLC program via the GSM network, so there is no need to drive to site to make a change.

VENDOR RESPONSES

Product

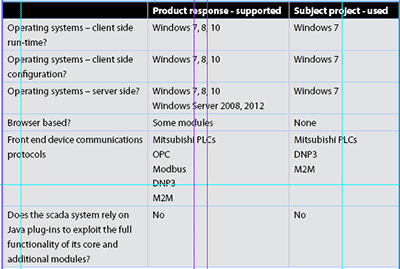

(Table 1.)

Q: Vendor comments on product/modules?

Adroit 8.4.2 in this project offers more robust communication.

Operating systems/VMware

(Table 2.)

Licensing, maintenance and support model

Q: What sort of licensing agreement options are offered?

Licensing is scanned I/O based – all internal logs are free, including alarms and historical log tags with databases. Base licence comprises core modules, which differ for the size of system you have.

Additional value adding modules can be purchased separately.

Q: Are licences sold outright or subject to periodic (eg annual) renewal?

Outright with technology support/maintenance agreement optional. Licence is a once-off purchase per major version release. Small version updates are free.

Q: What upgrade agreements are offered?

Groupwide support and sales arrangements are available along with maintenance agreements.

Minor version and patch upgrades are free.

Q: What after-sales offerings iro support and maintenance are available, and which technologies are used to deliver them?

Site auditing and onsite support can be offered as an annual agreement. Telephonic and remote desktop support is offered free during office hours.

Q: Do you have a documented process in place to manage and test OS patches and to release scada system software patches?

Yes, our testing department has a testing procedure to test Adroit products against latest Windows releases and upgrades.

Technology incorporated

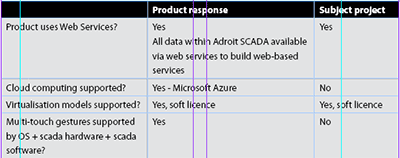

(Table 3.)

Q: What new technology has been introduced into the product in the last 12 months?

Smaller HMI package module, Mitsubishi FX5 M2M support, GIS, EMS solutions based on the product.

Integration and reporting

Q: What generic and/or product specific interfaces does the product have iro well-known MES packages?

Excell, SQL Server, MS Reporting Services – built on MS Business Intelligence technologies is the Adroit Smart Intelligence product.

Q: What native historical data reporting options are available?

Adroit has its standard flat file data logging that is used for trending and charts. Adroit can also log to multiple different databases. Microsoft SQL, Oracle, etc. Adroit SCADA interface can then also be used to create simple data queries to report data in the interface. Microsoft Reporting Services can then also be hosted in the user interface via url tool.

Maintenance, reliability and asset optimisation

Q: What maintenance, reliability, asset optimisation and/or continuous improvement related modules or capabilities does the product incorporate?

SNMP capability – possible to monitor LAN performance and IT infrastructure. All software changes and processes are logged to Microsoft Windows Events with a unique ID for Adroit. Adroit can also log this data to SQL if need be. Adroit offers Report Suite which comes with free audit reports for the system.

PLC configuration and programming

Q: What capabilities does the scada offer in terms of generation and/or management of PLC configuration files or PLC application code?

MAPS (Mitsubishi Adroit Process Suite) supports object-based generation of function blocks and scada objects in the Mitsubishi Electric range of PLCs.

Security and data protection

Q: What authentication, authorisation and role management models are available for the runtime environment?

Supports full MS security and all data encrypted between Adroit SCADA and client.

Unique selling proposition (USP)

Q: List the top five feature/benefit pairs that contribute to this product’s USP.

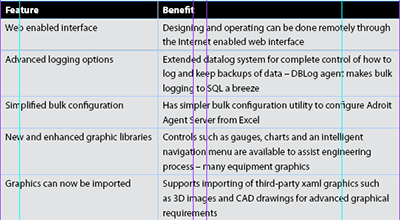

(Table 4.)

To view the unabridged version of this scada review, please visit http://instrumentation.co.za/+J928

| Tel: | +27 11 658 8100 |

| Fax: | +27 11 658 8101 |

| Email: | [email protected] |

| www: | www.adroit.co.za |

| Articles: | More information and articles about Adroit Technologies |

© Technews Publishing (Pty) Ltd | All Rights Reserved