Boiler drum level monitoring

April 2016

Level Measurement & Control

The importance of water level monitoring in a boiler drum cannot be over-emphasised. Very high level may result in erosive wet steam causing damage to downstream equipments including turbine. Very low level may cause over-heating, leading to tube failure and possible explosion. Hence all boiler regulations require continuous monitoring of boiler drum water level.

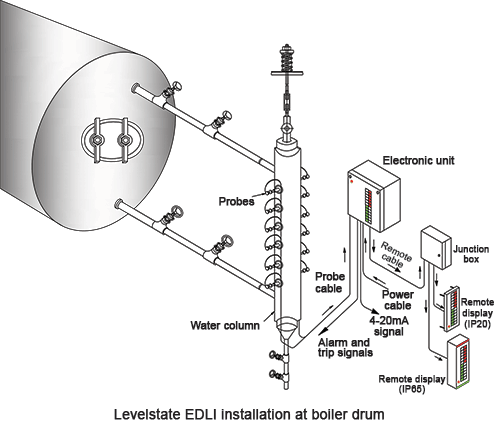

Levelstate Systems manufactures the Electronic Drum Level Indicator (EDLI) designed specifically for this application. This advanced electronic level monitoring system is based on the conductivity principle, a proven and accepted technique.

The EDLI eliminates the need for periodic maintenance or calibration, unlike some other level monitoring solutions. Other features include:

• The standard system is available for pressure ratings up to 207 bar @ saturated temperature.

• A choice 8-48 channels for various levels of visibility.

• Self diagnostic features to detect open-circuit/short-circuit/probe contamination/internal component and ground failure.

• Fully validated trip logic eliminates spurious trip.

• Configurable multiple SPCO/DPCO relay outputs with energised/de-energised and time delay output options.

• Multiple remote display facility.

• Opto-isolated dual 4-20 mA analog output.

• Digital water level indicator in mm (optional).

• Also available for hazardous zone (explosion proof) and super-critical applications.

Principle of operation

The EDLI uses the well-established principle of resistivity discrimination between steam and water to provide a clear indication of water level in a boiler drum. The discrimination between steam and water is based on the significant difference in resistivity between the two states over the saturation range.

The sensing element is a probe with an insulated tip inserted in a side-arm water column. Each probe is connected to its own sensing and indication circuit. When the probe is immersed in water, conduction occurs between the tip and the inside wall of the column. An open circuit occurs when it is in steam state. A vertical display of multiple green/red high intensity LEDs gives the level indication. The detection level is dependent on water purity and boiler operating conditions.

For more information contact Levelstate Systems, +44 1420 565402, shekhar@levelstate.com, www.levelstate.com

Further reading:

Cloud-based inventory management software

Endress+Hauser South Africa

Level Measurement & Control

Netilion is an award-winning cloud-based IIoT ecosystem designed for industrial processes. It connects the physical and digital worlds to send valuable information from the field straight to your phone, tablet or other device.

Read more...

Level sensing, conveyor control and grid resistors

DRH Components

Editor's Choice Level Measurement & Control

DRH Components is a specialist electric component and systems supplier with a focus on the control of electric motors. As part of its wide variety of products, the company markets the entire Bindicator range. Bindicator manufactures sensors for dry bulk and liquid level measurement.

Read more...

Level measurement under extreme plant processing conditions

VEGA Controls SA

Level Measurement & Control

Level measurement in LNG and LPG processes is about answering the simple question: “How much product is in the tank?” However, obtaining an exact value is not easy. The products are often under pressure, cryogenic, and highly explosive. Sensors from Vega have been operating successfully in all stages of the LNG/LPG process for many years.

Read more...

Grounding of hydrostatic level sensors

WIKA Instruments

Level Measurement & Control

Hydrostatic level sensors are very often installed in outdoor applications, primarily in the water and wastewater industries. A good connection to ground is essential when installing hydrostatic level sensors, since no grounding or poor grounding can result in destruction or damage to the level sensor.

Read more...

VEGA expands radar portfolio for factory automation

VEGA Controls SA

Editor's Choice Level Measurement & Control

VEGA is known worldwide for ensuring safe and stable processes with its level and pressure sensors, even under the most difficult conditions. The world market leader is now putting the finishing touches to its radar level portfolio, especially to meet the demands of fast processes in factory automation.

Read more...

Factory automation made easy

VEGA Controls SA

Level Measurement & Control

With the introduction of VEGAPULS 42, instrumentation specialist, VEGA is bringing its extensive experience with radar measurement technology to factory automation.

Read more...

The ultimate outdoor sensing solution

Turck Banner Southern Africa

Level Measurement & Control

Turck Banner’s T30R series has been expanded with a new long-range model. This sensor can accurately recognise and measure targets up to 25 m away, which is a 10 m increase over previous models.

Read more...

Non-nuclear density measurement

Morton Controls

Level Measurement & Control

Red Meters are changing the way industry measures density of slurries and dry bulk with its range of non-nuclear meters. Measurement data is shown in real time. Combined with software called Ruby, the

...

Read more...

Accurate measurement of moisture

Morton Controls

Level Measurement & Control

Harrer & Kassen GmbH is an expert in the field of microwave and NIR measuring techniques. HK provides the development and manufacturing of progressive, reliable and advanced instruments for moisture

...

Read more...

Suspended solids and turbidity measurement

Level Measurement & Control

Quadbeam sensors provide a continuous and accurate measurement of suspended solids and turbidity. The sensor uses a four-beam measurement principle that self-compensates for common measurement errors

...

Read more...