“With the growing local demand for economical yet efficient linear systems, BMG has established a partnership with OME Technology to supply and support STAF linear motion components. This range is known globally for high speed and precision, easy integration and interchangeability, energy saving and environmental protection,” says Rouff Essop, general manager, bearings division, BMG. “STAF linear motion products are used in diverse applications, including welding, soldering and drilling; industrial machinery; measuring and inspection; printing, scanning and packaging; assembly plants and warehousing, as well as in robotic arms and manipulators.”

Principles of operation

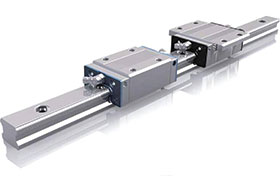

Linear guides – the key part of precision instruments – are used in conjunction with compact ball screws which are locked onto a platform and linked to a servo motor, to produce linear motion. The main function of the guide is to allow the platform to maintain high precision, high rigidity and high load motion.

STAF linear guides have a common rail, interchangeable alloy steel slide, designed for reliability and flexibility. The dust sealing twin lip structure ensures effective sealing and the large internal lubricant storage facility reduces maintenance requirements and extends the service life of the system.

Cage and non-cage types, which are fitted on the same profile rail, have new patented features which include a ball re-circulation design, with no gap, for smooth running. The newly designed chain lubrication system reduces friction during operation and extends service life of the system.

The BGC cage-type linear guides, which are suitable for high-speed applications, contain lubricant between the steel balls. The friction produced during operation is reduced by the oil film. Advantages over conventional systems include reduced contact pressure, lower noise levels, less vibration and lower heat generation.

In traditional guides, the steel balls collide, producing a sharp, screeching noise and are easily worn out. BGC linear guide cages are manufactured from macro-molecule polymer, with lubricant space designed within the chain belt. With the flexibility of the chain belt and the cushioning effect of the lubricating oil, most of the noise produced from the chasing effect of the steel balls is eliminated.

The BGC steel ball retainer has a fixed distance retaining function so that each steel ball receives a balanced force for stable operation and extended service life. The issue of irregular gaps is far smaller than with traditional linear guides.

The BGX non-cage series, with a four-groove design, ensures even load capacity in all directions, irrespective of how the rails are mounted. An auto adjust capability prevents assembly errors and allows quick, accurate linear motion by eliminating the deviation of the mounting planes. Advantages of this four-groove series over the conventional two-groove design, include quick, light movements, reduced friction, high load ratings and improved stability.

Accuracy

The accuracy of linear guides depends on the efficiency of circulation of steel balls between the slide and the rail. The incursion of the smallest objects can cause skipping and bumping of the slide and lead to permanent damage.

The advanced seal design of the BGX series is divided into top and bottom seals systems to prevent the incursion of foreign objects. The top seal system prevents particles caught at the rail holes from entering the circulation groove and the bottom seal system prevents objects from entering through the gap in between the slide and rail.

STAF has also developed micro linear guides – the MBX and MBC series, with an integrated dust-proof design and an efficient lubrication system. These miniaturised cage and non-cage types, have application advantages that include high precision, low noise levels and extended service life.

These linear motion systems are manufactured in Taiwan according to stringent international quality and safety specifications, including ISO 9001 certification and have RoHS compliance.

For more information contact Rouff Essop, Bearing Man Group, +27 (0)31 576 6200, [email protected], www.bmgworld.net

| Tel: | +27 11 620 1500 |

| Fax: | 086 670 3337 |

| Email: | [email protected] |

| www: | www.bmgworld.net |

| Articles: | More information and articles about Bearing Man Group t/a BMG |

© Technews Publishing (Pty) Ltd | All Rights Reserved