Yokogawa’s experience with magnetic flowmeters spans many decades and today the meters provide flexible configurations for industrial use in most processes, thanks to a broad product range and comprehensive options list.

AC and pulsed DC excitation

The magnetic flowmeter takes its name from the magnetic field that must be present within the flowtube in order to generate a flow signal. Fifty years ago, electromagnets were first utilised for this purpose, and were powered with AC voltage. The AC power generated sufficient magnetic flux density to get useful flow signals from vacuum tube amplifiers. Then, the development of transistors, integrated circuits, processors and digital technology, excitation power to the coils was reinvented from AC to pulsed DC power.

The constant magnetic field generated by the coils allowed one non-flow related error signal to be eliminated. This greatly improved magmeter zero stability and was a significant breakthrough leading to industry acceptance of this flowmeter technology.

Due to the technologies that were first in use, the change from AC to pulsed DC excitation also caused a drop in the excitation current < 100 mA, coinciding with the change in excitation frequency from 50/60 Hz to the lower frequency of approximately 6 Hz, which negatively impacted the magmeter’s immunity to flow noise.

Flow noise occurs with many liquids and applications and has many different causes, but in the end it is the result of an unstable electrolytic voltage. This fluctuating electrolytic voltage makes it impossible to extract the flow signal in a stable condition. This explains why both AC and pulsed DC type meters remain in use today. However, this was not so for Yokogawa. The advantages of high frequency excitation and low frequency excitation were carefully studied and it was clear from the very beginning of the Yokogawa magmeter development that a commercially acceptable solution was needed that would combine the advantages of both methods to produce a new excitation concept: Dual frequency excitation.

The milestones in the development of this Yokogawa technology were:

• Accomplishment of high zero stability from low frequency pulsed DC technology for high accuracy.

• Accomplishment of high excitation current for a strong magnetic field, the basis for a superior signal/noise ratio.

• Accomplishment of high frequency excitation for generating stable flow signals with a fast response time, even when unstable electrolytic voltages (flow noise) are present.

Painstaking research into material selection, signal conditioning, and magnetic field management eventually delivered the Yokogawa technology breakthrough of dual frequency excitation: The permanent side-by-side presence of two different excitation frequencies.

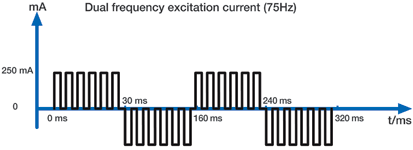

The use of specialised magnetic materials capable of suppressing eddy currents together with special excitation voltage conditioning enables Yokogawa to switch a high 250 mA excitation current in a few milliseconds. Providing flow data every 13 ms from the high 75 Hz excitation frequency improves flowmeter performance by a factor of 10 compared to standard pulsed DC type magmeters.

With the Yokogawa AXF magmeter family, even an enhanced 160 Hz excitation frequency is possible, making the non-intrusive magmeter principle attractive in the most challenging applications.

One common application for the dual frequency excitation technique occurs when batches are of a short duration, for example, having filling times below one second. For the required accuracy, it is essential to generate flow data with response times ranging from 10 to 20 ms. One special but very common application is the measurement of water with conductivity as low as 1 S/cm. Low conductivity water generates so much flow noise that standard pulsed DC meters do not work at all. For low conductivity fluids like de-ionised water, only dual frequency magmeters with high excitation currents and high excitation frequencies can deliver performance in such applications.

For more information contact Christie Cronje, Yokogawa South Africa, +27 (0)11 831 6300, christie.cronje@za.yokogawa.com, www.yokogawa.com/za

| Tel: | +27 11 831 6300 |

| Fax: | +27 11 86 411 8144 |

| Email: | yma.info-za@yokogawa.com |

| www: | www.yokogawa.com/za |

| Articles: | More information and articles about Yokogawa South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved