Click here for .pdf file.

End-user details

Name: Details withheld at reviewer request

SI details

Name: Deon Korb

Designation: Systems engineer

Company: Advansys

Phone: +27 (0)11 595 8450

E-mail: [email protected]

Product details

Product name and version: Wonderware ArchestrA System Platform with InTouch 2012

Vendor: Invensys Operations Management Southern Africa

Phone: 0861 WONDER (0861 966 337) +27 (0)11 607 8100

E-mail: [email protected]

URL: www.wonderware.co.za

Application details

Location: Impala Platinum, Platinum Metal Refinery, Springs

Industry: Mineral processing

Application: Platinum refining

Server OS: Windows 2008 Server Enterprise R2 64-bit

Client OS: Windows 2003 Server Standard R2 Terminal server application (thin clients) Windows XP SP3 (old nodes)

Application statistics

Tag count: Approximately 2500

Updates per day: Approximately 4 320 000

Front ends: Unknown I/O count across multiple Texas Instruments PLCs. These specifics were outside of the scope of this project .

Licences: The existing standard InTouch and Historian licences were upgraded to ArchestrA System Platform licences

END-USER RESPONSES

General

Q: Briefly describe the application including information on any pre-existing control system.

The project scope called for the upgrade of a standard InTouch system to an ArchestrA system.

Q: What was the primary motivation for the project?

To benefit from the improved scalability and connectivity offered by the ArchestrA System Platform.

Q: What were the main goals established for the project?

The main goal of this project was to develop new standards during the upgrade. This was achieved as we now have an application that is well structured, looks good and is easy to use.

Licensing, maintenance and support

Q: What upgrade agreements are in place for this application?

Upgrades are covered under an annual support agreement.

Q: How is after-sales support handled on this application?

Support is covered under a paid annual support agreement.

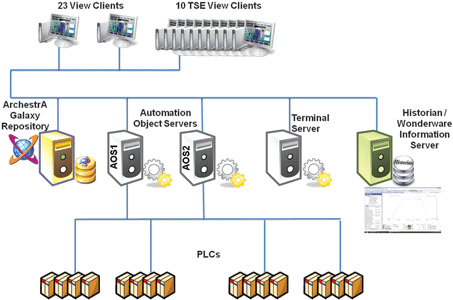

System architecture

Q: Is the scada system integrated onto an intranet or the Internet? If so, what level of remote monitoring and control is configured?

Managers are connected via InTouch FactoryFocus. This is a view-only application on their desktop.

Q: Do you run the scada in conjunction with any third-party application software (Other than MES)?

No.

Management reporting and integration

Q: Does the application include data archiving / historian capabilities with an historical data reporting system?

Yes. We use the Wonderware Historian for archiving and Historian Client at plant level and on the business network level.

Q: Is the system integrated with an MES / ERP or other management reporting or control system? (e.g. Baan, SAP, SYSPRO…)

Yes. It connects to AspenTech.

Q: Who performed the above system integration and was any additional software development needed to accomplish this?

No additional software development was needed.

Q: Have any production benchmarking tools been configured as part of the scada system?

No.

Q: Has any asset management functionality been configured in the application (for software assets, control system assets or for plant assets)?

No.

Q: Has any GIS (Geographic Information Systems) functionality been configured in the application?

No.

Q: Are you using tablet PCs or mobile phones to interact with this scada system?

No.

End-user conclusion

Q: What was the predominant feature (or features) that made you decide to purchase this scada product over all others for this application?

This was our natural product upgrade path. The support from the vendor and SI also influenced our decision.

SI RESPONSES

Project details

Q: Approximately how many man-hours did the scada configuration take?

640 man-hours in total. This included the development of the navigational framework and control module standards and 300 man-hours of HMI configuration.

Q: What tools were used to minimise the man-hours taken?

* System Platform CSV Import/Export utility to rapidly derive and configure the objects.

* Migration utility from the old application to the new one.

: What human factors were taken into consideration in the HMI design process?

* Rapid navigation (two clicks to get to any page).

* Aggregated alarm counts built into the menu structure, thus guiding the operator to the alarmed device.

* Colour limited to abnormal conditions.

* Modal confirmation popups for all PLC write actions.

Q: For the graphics development process did you use standard library images, or did you have to draw images from scratch?

Both. Standard graphics were used for the systems monitoring pages. Custom templates were developed to precisely match the customer requirements at the device level.

Q: How would you describe the library of graphic images?

The standard library is comprehensive, but too focused on aesthetic appeal.

Q: Did you use any ‘special’ images (e.g. photographs, 3D images, specialised dashboards, etc.)?

No.

Q: Did you use any video or multimedia technology in the application?

No.

Q: What alarm management standards or best practices were adopted in configuring the scada system alarms?

Alarms are generated inside of System Platform and are solely used for visualisation. Alarms can be rapidly traced using an aggregated model view displaying the alarm counts in the menu structure, thereby enabling the operator to quickly view the alarms in either the plant mimic or a contextual alarm control.

Q: What structured processes were followed to determine expected performance under full load, and during abnormal failure conditions?

In-place testing was conducted. The system load is not expected to fluctuate and node losses have predictable results.

Q: What are the key physical communication layers and communication protocols employed in the system?

The system uses a copper and fibre Ethernet network for the Galaxy communications.

Q: What levels of redundancy are incor-porated in this scada application?

No redundancy is implemented yet. Future redundancy requirements have been included in the design.

Q: What specific custom code or scada scripts were written for this project?

* The control modules were scripted inside System Platform, avoiding the need PLC code modifications.

* Auto population of a full Historian Client trend control to display page-related contextual trends.

* Alarm control was called with a custom alarm query to display page-related contextual alarms.

Security and data protection

Q: How have authentication, authorisation and role management been configured?

OS groups were defined using Active Directory on a dedicated plant domain controller. Groups were set up by security area and roles, such as – Operators and - Engineers.

Q: Does the design make provision for a DMZ and firewall segregation of process (scada) network and business networks?

No. Impala Refinery uses completely separated networks for business, HMI and PLCs.

Q: What intrusion detection has been incorporated on the plant network(s) on which this scada system exists?

None.

Q: What configuration backup and data archive backup methodologies have been adopted?

Backup and archiving are handled by the end-user.

Q: Did you use any integrated or third-party configuration control system for the scada configuration during the engineering of this application?

No.

SI conclusion

Q: How would you rate the ease of use of the historical reporting system?

No reporting tools were employed. The Historian Client tools are used to view historical data. These controls are extremely feature-rich and powerful for fault finding.

Q: What impresses you the most about the engineering / configuration aspects of the product now that it is in operation?

The object-oriented approach of System Platform makes develop once, use many times a pleasure to use. A well-designed and tested template can be used throughout the plant with no extra development required.

Q: What impresses you most about the architecture?

The architecture allows for massive scaling. The templates developed for the plant can be used to derive instances for the entire plant. This model can then be deployed to the required hardware. The architecture in place can now be used for any size application.

VENDOR RESPONSES

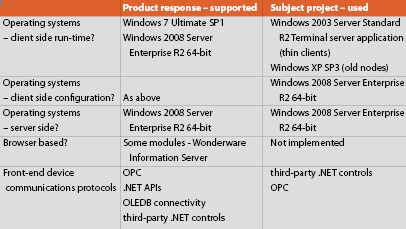

Product

See Table 1.

Q: Vendor comments on product / modules?

ArchestrA System Platform provides a common, highly efficient and centralised software infra-structure to develop, manage, control and maintain industrial applications with exceptional scalability and openness. Wonderware InTouch helps identify and act on inefficiencies, non-optimised processes and process conditions in alarm, so that problems can be minimised and business performance optimised.

With InTouch’s re-usable, pre-tested ArchestrA graphics implementation risk is lowered, standards are enforced, application revision control is simplified and operator consistency is improved.

Operating systems / VMware

See Table 2.

Q: Vendor comments on operating systems

The close relationship between Wonderware and Microsoft helps to ensure high-quality software coordinated with the Microsoft development roadmap, conceived to work on and thoroughly tested with Microsoft software.

Licensing, maintenance and support model

Q: What sort of licensing agreement options are offered?

Licences are based on the functionality or modules that are required for the specific solution.

Q: Are licences sold outright or subject to periodic (e.g. annual) renewal?

Licence is a once-off purchase for a particular version.

Q: What upgrade agreements are offered?

Customer First is a comprehensive support network that allows for software technical support as well as version upgrades for purchased modules. Customer First requires annual renewal in order to use the service.

Q: What after-sales offerings iro support and maintenance are available, and which technologies are used to deliver them?

The Customer First program is available in four tiers. Each tier includes support services for both hardware and software products with elements such as parts replacement, version upgrades, and technical support and access to a wide range of additional, optional services such as application support, on-site resources and value-added consulting.

Invensys also offers advanced remote monitoring technology that enhances its ability to deliver higher availability and reliability of plant assets to customers.

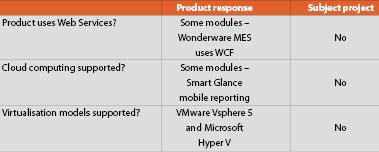

Technology incorporated

See Table 3.

Q: What new technology has been introduced into the product in the last 12 months?

ArchestrA System Platform 2012 R2, offering:

* Higher information availability.

* Larger systems and improved Historian data capacity.

* Improved data integrity.

* Global system unification with improved security.

* An holistic view of contextualised data.

Management reporting and integration

Q: What native historical data reporting options are available?

Wonderware Historian Client generates real-time and historical data charts and reports directly from the Wonderware Historian. Data can be viewed, analysed and consumed via a desktop application, web browsers or by external applications such as Microsoft Office, Wonderware’s InTouch HMI or custom clients.

Reports and data charts from Wonderware Historian Client can be integrated with information from other Wonderware applications and made available over the Web using Wonderware Information Server.

Q: What product specific interfaces does the product have iro well-known MES packages?

Wonderware Enterprise Integrator offers powerful site to enterprise integration capabilities. Interface technologies supported include Web Services, File Drop, FTP, MSMQ, XML, HTTP, and SOAP, B2MML message definitions based upon ISA-S95 standards and message repository leveraging MS SQL Server.

PLC configuration and programming

Q: What capabilities does the scada offer in terms of generation and/or management of PLC configuration files or PLC application code?

ArchestrA System Platform has the capability of auto-assigning PLC addresses to configured field inputs, keeping the functionality of maintaining the PLC tag database in the PLC level.

Security and data protection

Q: What authentication, authorisation and role management models are available for the runtime environment?

All modules support Microsoft Active Directory. User/Groups are mapped to functional roles.

The different functional roles associated with specific privileges are configured in the specific product modules.

Unique selling proposition (USP)

Q: List the top five feature/benefit pairs that contribute to this product’s USP.

* Enables integration of the entire enterprise – provides a unified approach towards improving business efficiency.

* Lowers engineering costs – improves competitiveness.

* Easily scales as the business grows – safeguards existing investments.

* Enforces engineering and operating standards – reduces engineering costs and provides a common base for SIs and third parties.

* Improves control without costly system replacement – system upgrades improve existing assets rather than call for their replacement.

© Technews Publishing (Pty) Ltd | All Rights Reserved