The L-Gage LTF laser sensor from Banner Engineering provides precision measurement and reliable detection of difficult targets over distance.

Using time-of-flight technology, the LTF can accurately measure distance from up to 12 m away without a retro target. It measures distance by emitting pulsed light and calculating the amount of time for the light to reflect off the object and return to the sensor.

The LTF can be used to solve many long-range industrial measurement applications, including part-in-place, part profiling, part positioning, fill level, roll diameter and web tension control. The LTF is a high-performance sensor offering a best-in-class combination of range, repeatability and accuracy. The same sensor that provides repeatability of less than 3 mm and accuracy of plus or minus 10 mm can also reliably detect dark targets at 7 m and white targets at 12 m. The high excess gain, superior signal control and automatic adaptive laser power control offered by the LTF ensure reliable detection of challenging dark and reflective targets from a distance.

“The LTF offers users an outstanding combination of range, repeatability and accuracy,” said Brad Ragozzino, technical marketing engineer at Banner Engineering. “With high excess gain, high reliability and durable performance, the LTF ensures accurate sensing for challenging targets. In addition to precision distance measurement, the LTF delivers consistent detection of targets regardless of the angle, environmental conditions or ambient light. This dynamically adjusted laser sensor can also sense objects with varying materials and shapes. The laser power increases output for dark targets or objects at steep angles, while reducing power for shiny targets.”

To satisfy applications in harsh environmental conditions, the LTF features durable IP67-rated die-cast zinc housing. LTF series sensors come ready to measure right out of the box. The sensor can be quickly mounted, aligned and provide real-time measurement. It has a Class 2 laser emitter with a small, highly visible spot to facilitate sensor alignment. It features an intuitive, easy-to-use menu that is accessed via an easy to read two-line, eight-character LCD display. Four on-board touch buttons allow the operator to navigate the menu, set inspection parameters and configure the sensor. Users can select from several Teach modes, including 2-point teach, mid-point teach, switch point teach and push button adjust, to accommodate diverse applications. Advanced measurement modes, delay timers and cross-talk avoidance capability are also available. Additionally, three bright LED indicators provide clear status indication for analog output, discrete output and power.

Typical applications

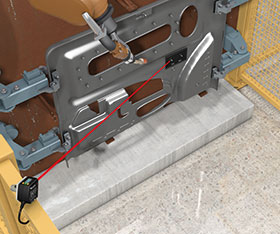

Error proofing: part presence and position verification on a car door from a distance.

Before the inner and outer panels of a car door can be joined together, structural, sound proofing and other components necessary to the systems housed in the door must be fastened into place. During this process, a small aluminium component will be welded onto the inner panel of a door. The part will be placed into position and then conveyed to a robotic work cell where it will be welded. If the component is missing or incorrectly placed when the weld is made the door panel will be unusable.

A single LTF series sensor is installed on the hard guarding surrounding the weld cell, approximately eight metres from and at an angle to the target. At this distance the sensor will not come into contact with equipment or be exposed to hazards inside the weld cell. The exceptional linearity, repeatability and resolution offered by the LTF ensure that the part will be detected in the correct position and any variations will result in an output sent to stop the robot before welding begins.

Fill level: monitoring content levels inside a high-volume hopper.

Chewing gum is massed in a high capacity hopper situated atop an extruder. Gum is continuously conveyed into the hopper. Problems with the delivery system and other errors can result in inadequate amounts of gum being processed through the system. Errors inside the extruder or the hopper can cause the system to backup, even overflow. Constant monitoring of the hoppers contents can help identify problems and reduce lost product and productivity.

A single LTF sensor is installed more than a metre and a half from the hopper infeed. At this distance, the sensor will not interfere with system operations or come into contact with the equipment or the gum. The sensor’s analog output is configured to regulate the rate at which the gum is supplied to the hopper. If the amount of chewing gum should ever exceed the limits established by the operator during inspection setup, the discrete output will trigger the supply feed to shut down.

Loop control: monitoring shiny black tread rubber during tyre production.

During the manufacture of a tyre, tread rubber is processed through a calendering machine before being cut to length. Excessive or insufficient tension can distort or damage this material, making it unusable.

Loops of slack material between processes regulate this tension. These loops must be closely monitored and machine speed adjusted to maintain proper tension on the material. However, the colour and sheen of this material makes consistent and accurate detection difficult for most sensing technologies.

LTF series laser measurement sensors offer tremendous accuracy over distances and are unaffected by target colour or reflectivity, making them an ideal solution for monitoring the loops of tread rubber. Deployed over the loop, the LTF continuously measures the distance from the sensor to the lowest point of the loop. The analog output makes constant adjustments to machine speed to regulate web tension and the discrete output is configured to trigger an alarm if loop size falls outside of operator assigned parameters at any time.

For more information contact Brandon Topham, RET Automation, +27 (0)11 453 2468, [email protected], www.retautomation.com

| Tel: | +27 11 453 2468 |

| Email: | [email protected] |

| www: | www.turckbanner.co.za |

| Articles: | More information and articles about Turck Banner Southern Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved