Richards Bay Coal Terminal (RBCT) is the single largest coal export terminal in the world. Opened in 1976 with an original capacity of 12 million tons per annum, it has grown into an advanced 24-hour operation with a design capacity of 91 million tpa.

The company equipment includes 5 tipplers, 10 stacker-reclaimers, 4 ship loaders and a number of high-speed conveyors. However, the existing terminal control system (TCS) no longer aligned with RBCT’s engineering technology vision and required, in some cases, critical software upgrades and in others complete replacement of critical but obsolete products. This project consisted of upgrading and replacing parts of the TCS and incorporating the result into a Wonderware System Platform environment.

Background

Today, industrial automation systems boast of openness, scalability, flexibility and other attributes that assure their prospective users of a sound investment for the future. But what of systems that were developed and installed before such qualities were given the importance they enjoy today? Some of them may prove too difficult or impossible to integrate into today’s technology. Replacing such a system is a bit like performing a heart transplant – in either case, a botched job does not end well for the patient. This was especially real to RBCT because previous upgrade attempts took five years and were not successful.

That is why the latest TCS upgrade and replacement at RBCT was done with the utmost care, the best engineering know how and proven future-proof technologies. RBCT faced the following challenges with the existing system:

• Operators and maintenance personnel look at different plant screens, which make faultfinding and communication difficult when it should be transparent.

• There is no plant-wide standards-based strategy (such as between the TCS and PLCs).

• The system is mature and any change requires plant downtime. In addition, the lack of adequate documentation makes these changes risky.

• The Oracle (database) and Gensym G2 (real-time management of mission-critical systems) software required an upgrade to the latest versions.

• The plant HMI and plant data software were obsolete and failing due to the system upgrades around them.

• The existing Wonderware plant InTouch required standardisation, easier deployment and a facelift.

• The existing Unix-based TCS required specialised technical skill in multiple areas.

“In view of this, the project was approved based on current risk rather than new or improved functionality or capacity,” says Ingrid-Gaye Osborne, director projects, Saryx Information Systems. “During a recent computer controls risk audit, the current environment was identified as the number one risk that the organisation faced. The very high likelihood of failure would result in an extreme impact on the business should it occur. Preventing such a calamity was the ultimate objective of this project.”

The project scope stipulated that the current environment must be replaced like for like, which resulted in a four-phase implementation:

• Phase I – TCS stabilisation (2014).

• Phase II – Single Sub – (2015).

• Phase III – Machine standards – (2016).

• Phase IV – Machine standards – (2017).

Current RBCT plant overview

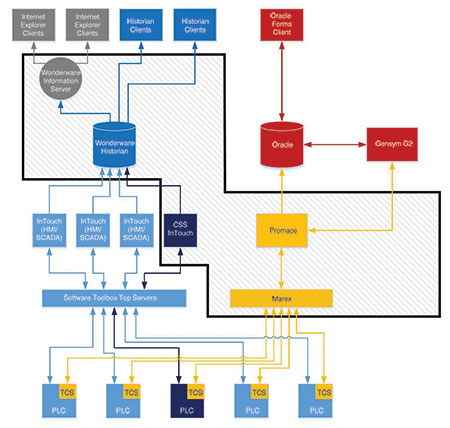

The existing plant software infrastructure (Figure 1) is based on a Wonderware InTouch, Oracle database, Gensym G2 and Promace configuration. Two separate applications exist and these were included in the scope of works for this project: The TCS is the MES/MIS plant control application familiar to the control room operators and other RBCT personnel and the Central Single-Sub (CSS) application, which is a supervisory HMI used by the PC&A department for maintenance. Several peripheral supervisory HMI applications exist across the plant, but these fall outside the current scope of works for this project.

There are approximately 45 PLCs installed throughout the plant, which form the backbone of the equipment control system. Three Top Servers from Software Toolbox are used exclusively by the supervisory level HMI InTouch Applications to connect to these PLCs. A custom Marex interface (driver) facilitates communication to each of the PLCs for communication to the TCS plant control application. This driver was decommissioned during the project.

Wonderware’s InTouch application runs on each of the various substations and for each of the major equipment types including tipplers, stacker-reclaimers and shiploaders, to allow for supervisory and control functions. One of these applications is created on the CSS and has been replaced. All InTouch applications connect to the plant via the Top Servers and store historical data in a central Wonderware Historian, which was upgraded as part of this project.

The Wonderware Information Server (WIS) is used as a web portal on top of the Historian. The portal can be used to access historical reports and trends and for the visualisation of the live plant environment by linking directly to the InTouch Applications.

Gensym G2 is the MES platform at RBCT and will be upgraded to the latest version as part of this project while the Oracle database is host to the Operational Planning and Control (OPC) system and the TCS.

Implementation

The project was initiated at the beginning of 2014 and was completed in December 2015. This was critical, as equipment replacement of two stacker-reclaimers and two shiploaders began in 2016, and development for this equipment must be incorporated in the new software prior to this.

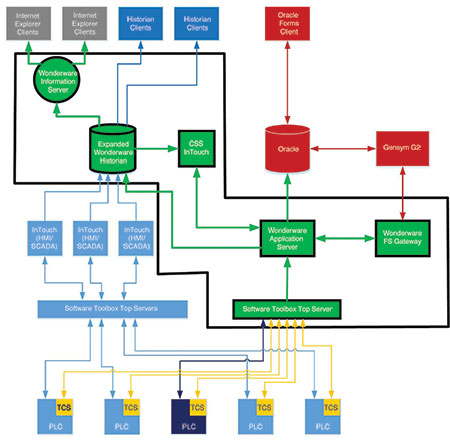

The new topology is shown in Figure 2 where an additional Top Server layer provides connectivity to the PLCs for the TCS application. The CSS application is also routed through this layer.

The Wonderware Application Server is the backbone of System Platform and connects to the plant using the new Top Server layer. The Application Server hosts the various applications according to a hierarchical model. FSGateway is the Wonderware I/O router. It provides a DDE, SuiteLink and OPC server on top of Application Server. This makes all the attributes in Application Server available to Gensym G2 via OPC.

InTouch is the new visualisation client running inside the System Platform framework. The InTouch applications are not connected to the plant directly, but get information from the Application Server. InTouch is the HMI for the TCS as well as the CSS applications.

The current Historian was replaced with a larger version of itself and forms part of System Platform. The Application Server sends historical data to the new Historian and all the existing InTouch Application data is redirected to the new historian server for historical purposes. Existing historical data can also be transferred to the new Historian.

The existing Wonderware Information Server was replaced with a newer version and forms part of System Platform. This web portal allows users to connect to it via a web browser and provides access to published trends, reports, process graphics and a generic trending tool.

In addition, ACP ThinManager has been incorporated in order to provide Remote Desktop Services for the new InTouch clients. At a future stage, the existing InTouch Applications may then also be migrated into the ACP ThinManager environment.

MDT AutoSave has also been included to serve as the change control system that monitors the development taking place on all PLCs. It stores versions of the PLC software and allows an authorised user to roll back to previous working versions in the case of a problem. Companion product AutoSave for System Platform will do the same for Application Server and the new InTouch.

Benefits

This extensive and complicated project was designed to provide RBCT the following benefits:

• Removal of the risk of running obsolete products in a plant-critical system.

• Alignment with RBCT’s engineering technology vision.

• Improved system access control/security, software change control.

• Improvements in genealogy, traceability and data archiving.

• Centralised plant control environment.

• Better efficiency and effectiveness in the maintenance of information and calculations by reducing human errors.

• Improved interaction between control room plant operators and C&A technicians.

• Increased employee motivation and flexibility due to improved efficiency through their use of modern, user-friendly interfaces.

• Establishment of plant-wide standards.

• Closer integration between the MIS/MES layer and the PLCs.

• All the chosen technologies are widely used, proven, widely supported and can be managed with RBCT’s existing internal technical skills, providing improved plant stability and future scalability.

For more information contact Jaco Markwat, Wonderware Southern Africa, +27 (0)11 607 8100, jaco.markwat@wonderware.co.za, www.wonderware.co.za or Ingrid Osborne, Saryx, +27 (0)35 788 0486, ingrid@saryx.co.za, www.saryx.com

© Technews Publishing (Pty) Ltd | All Rights Reserved