Interoperability, by design, allows separate systems to interact seamlessly. This lends itself to the core idea of Ethernet: following the plug-and-play principle, devices made by different manufacturers should work together in a problem-free manner. As one of the factors leading to the success of the technology, interoperability is extremely important for the EtherCAT Industrial Ethernet protocol as well. With EtherCAT, interoperability can currently be found in the implementation and system architecture, and – together with the support of the EtherCAT Technology Group (ETG) – guarantees the seamless interaction of field devices from different manufacturers.

Interoperability – what does that mean?

First, it is important to explain what the term ‘interoperability’ actually means. In brief, interoperability is the ability of different systems to work together seamlessly. With regard to fieldbus technologies, whether traditional or modern with some take on Ethernet, interoperability also means the practical ability of field devices in the same network to interact among each other, even if they come from many different manufacturers.

In general, there is an important difference between traditional fieldbusses based on a so-called Shared Medium and the modern Ethernet-based fieldbuses.

One cable for all devices

The aforementioned Shared Medium provides data exchange between components with one or more computers participating in the process. The Shared Medium principle is better known by the term ‘bus’ which, looking at the Latin origin, means ‘for all’ or ‘with all’. Thus, fieldbus technology means that all field devices participating on one network – actuators as well as sensors – electrically use only one medium, a shared cable.

However, each device in contact with the cable generates impedance, slightly changing the electrical behaviour of the cable and causing attenuation and reflection of electrical signals. This attenuation limits the expansion of the network, not only in its length, but also in the number of connected devices. Significant disturbances to the system can occur as a result, which do not have to be near the source of the problem. Thus, facilitating interdependence between all participating fieldbus devices, as well as the corresponding troubleshooting, is complex.

Always peer-to-peer

In contrast, Ethernet, as used in the office environment, always has a point-to-point connection (also called peer-to-peer). Thus, electrical disturbances (including their associated effects) are limited from the start, as only two devices at the ends of the transmission path are involved. Protocol errors such as temporal misbehaviour do not affect the next device or even the one following after that, greatly simplifying error localisation.

As a result, Ethernet, as a foundational technology for demanding industrial Ethernet applications, initially has the potential to offer much better interoperability compared to traditional fieldbuses based on the Shared Medium principle mentioned above.

EtherCAT – like Ethernet but evolved

Of course, the industrial Ethernet protocol EtherCAT is Ethernet-based. It uses standard data frames coupled with the physical layers of the Ethernet standard IEEE 802.3, and additionally meets the requirements for industrial Ethernet ‘at the field level’. Examples here include hard real-time features with deterministic response times or the ability to integrate an almost unlimited number of devices into the network.

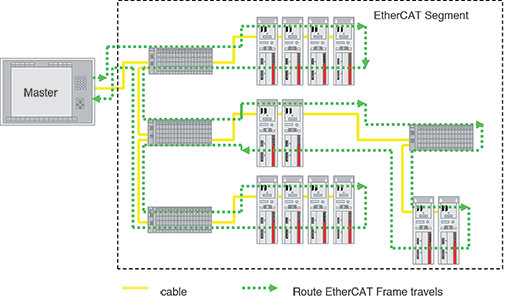

To master the challenges in the field as effectively as possible, EtherCAT uses a functional principle that is unique and delivers high performance at the same time: It processes the datagrams ‘on the fly’, as the frame travels through the network.

EtherCAT’s support of automatic addressing makes manual adjustments unnecessary and streamlines tasks such as configuration, diagnostics, and maintenance. For most applications, it is sufficient to send one EtherCAT datagram per cycle to address all devices. Due to the high efficiency of the EtherCAT datagrams, as well as its peer-to-peer physics, electromagnetic robustness is increased. Disturbances that occur are not only reliably detected, but also precisely located, greatly reducing the time needed to troubleshoot a system. For building up the network, EtherCAT does not require any switches or hubs, which eliminates collisions even for highly time-critical requirements. Additionally, each port of an EtherCAT device is equipped with its own error counters to enable precise diagnostics of the network.

EtherCAT and interoperability

Regarding interoperability, EtherCAT gets a high score when compared to other systems, especially when it comes to processing of the basic protocol. This is done in a special EtherCAT communication module, which guarantees datagram-processing functionality at a unique and virtually fixed processing speed every time. The remarkable variety of field devices available worldwide, as well as the number of master and configuration tool implementations, is evidence as to how well EtherCAT performs as an industrial fieldbus.

Consistent behaviour on all layers of the stack

As usual in communication, EtherCAT is described with the ISO/OSI layer model. With this structure, the consistent behaviour of EtherCAT devices can be explained very well.

The Physical Layer (PhL) describes the prerequisites to send and receive zeros and ones as electrical signals via an Ethernet cable. The modules (PHYs) convert the electrical analog signals into digital signals at both ends of the cable. The PhL defines the transmission speed as well as transmission mode, typically 100 Mbit/s, full duplex with EtherCAT.

The Data Link Layer (DLL) describes the datagram structure, addressing the individual devices involved as well as the processing order. This follows a simple principle with EtherCAT, as shown in Figure 1.

Because the datagram path is initially known, collisions are eliminated as a result. Additionally, this leads to a deterministic runtime under each condition.

The PhL, as well as the DLL, conform completely to IEEE standard 802.3, which is often used by routers, switches, and PCs. With EtherCAT, interoperability problems on the PhL or DLL can be almost completely eliminated. Since the device manufacturer does not have to implement this functionality, reliable processing of the DLL protocol on the hardware chip is guaranteed.

The Application Layer (AL) consists of two parts: the communication stack and the application stack. The communication stack handles all EtherCAT-relevant functions, such as those for the exchange of process data and parameters. Besides the synchronisation, this also includes error handling, which is processed in the EtherCAT State Machine. The EtherCAT State Machine implements the device functionality, the sensor measurement, or the functionality of a drive. The services and data structures are clearly defined; the content determines the functions of the single field devices, which are implemented in software by the device manufacturer.

In summary, the lower levels (PhL and DLL) in EtherCAT devices are interoperable due to the described structure and use, a perfect basis for the idea of plug-and-play. With EtherCAT, any caution areas to watch out for regarding interoperability are significantly limited. They only apply to functions implemented on the AL, such as in the application stack, EtherCAT master, and/or the configuration tool. The fact that the AL always shows a peer-to-peer relation between EtherCAT slaves and masters or the configuration tool is also a product of this simplification.

The further development of effective EtherCAT interoperability continues

Support for AL stacks

One of EtherCAT’s continued factors for success is the fact that there has been a slave stack from the beginning of the technology. This has become the quasi-reference for EtherCAT slave implementations among ETG members: the Slave Stack Code (SSC) itself is maintained by Beckhoff Automation. The continuous maintenance of the SSC, as well as its wide distribution, is another enabler for the consistent, interoperable behaviour of EtherCAT devices. Manufacturers get a reliable basis through which they can integrate their device’s specific functionality – without the need to change the basis of the AL, the communication stack itself.

Additionally, the ‘Object Dictionary Tool’, which can be downloaded with the free SSC, supports the description of all parameters and cyclic variables in a clearly arranged spreadsheet, generating the necessary data structures in the firmware files as well as the device description document. Developers can describe the so-called object dictionary in a consistent and error-free manner.

Interoperability around the world

Besides the specification of the mentioned test files, the ETG has established further mechanisms to develop and ensure interoperability for EtherCAT. Several times a year the organisation conducts gatherings known as EtherCAT Plug Fests in North America, Asia and Europe. At these events, more than 200 EtherCAT device developers meet each year to test their devices and guarantee interoperability.

Additionally, EtherCAT control manufacturers can benefit from the constantly growing EtherCAT interoperability networks, which developed and maintained with assistance from the ETG.

Version 1.0

Regarding interoperability, the EtherCAT protocol features are of special importance: The high performance of the EtherCAT protocol as it has been introduced in 2003 is still leading – even after 10 years. All EtherCAT devices are based on the protocol version 1.0 and neither device developers nor test engineer or users have to take care of devices with different protocol versions. Several technical working groups do specify new features. And that those are seamless additions and no changes is supervised by the Technical Advisory Board (TAB) of the ETG continuously. Thus a 2004 device does not have all the features of a 2014 device but nevertheless cooperates problem-free and interoperable in the same network.

Conclusion

Industrial environments require a particularly high level of reliability and simplicity from communication solutions. Plant systems have become increasingly extensive, so field devices must solve many more, and increasingly complex, tasks. Thus, a ‘single source’ principle is simply not possible when the basic prerequisite for the overall communication system is the ability to let the devices participating in a network interact problem-free with hardware and software. This idea of a seamless interaction is covered to a high degree by EtherCAT technology: Accompanied by the many supporting measures of the ETG, EtherCAT guarantees interoperability in the field initially and continuing well into the future.

For more information contact EtherCAT Technology Group, +49 911 540 56 226, [email protected], www.ethercat.org

© Technews Publishing (Pty) Ltd | All Rights Reserved