The device, with its new enhanced features, is a step from a data manager to a centralised monitoring and maintenance system for small solutions. The update of the Advanced Data Manager Memograph M platform completes the Endress+Hauser portfolio update. Two years ago, the launch of Ecograph T as a universal data manager was the first step in that direction.

HART input cards as a true USP

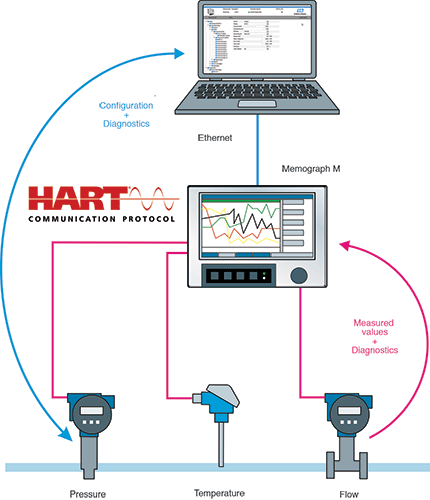

Besides the already existing universal inputs, Memograph M RSG45 offers up to 20 inputs for HART signals. The HART protocol is supported by most sensors in the field. With these inputs, the Memograph M can use the 4-20 mA signal as well as all four HART signals of a connected field device. Thus, the RSG45 allows the user to get more information from the field, which improves the process insight and increases the process safety. Since there is no analog to digital conversion with the HART protocol, the calculations done by Memograph M RSG45 are more accurate than the ones solely utilising analog signals. This results in cost savings, which is an added advantage in energy monitoring applications.

In addition, the device offers a HART gateway function. Therefore, the data manager allows direct access from the PC configuration software, FieldCare for example, to the field devices without the need for an additional HART modem or a loop interrupt. Thus, parameterisation of the field devices can be done easily and quickly from the control room. With the help of this feature, the detailed instrument health status is available as well. This helps simplify maintenance and troubleshooting.

This type of functionality is unique in the market for data managers.

Stainless steel front and ATEX Ex xp approval

Another highlight of Memograph M RSG45 is an optional resistant stainless steel front made of 316L. This robust panel can be used in critical environmental conditions. As it does not have any interfaces on the device front, the Memograph M RSG45 can be operated on-site via a capacitive touch screen when the stainless steel front is selected. This, along with mounting the unit in a pressurised enclosure system, makes the device appropriate for use in potentially explosive atmospheres, making safe data storage possible in ATEX Ex applications as well.

Communication and integration flexibility

Another new feature of Memograph M is the availability of the industrial Ethernet based communication protocols EtherNet/IP and Profinet. Both protocols are becoming more important in the process industry and help to increase application flexibility of the device. All other fieldbuses that were already integrated in the previous device, like Modbus RTU, Modbus TCP, and Profibus DP, will still be available as well on the Memograph M RSG45. This communication flexibility allows easy and cost-effective integration from the field level into the Ethernet based control levels and also minimises the commissioning time.

Also, WebDAV was implemented into the advanced data manager. WebDAV is an open standard to provide files on the Internet as an extension of the Hypertext Transfer Protocol (HTTP). By WebDAV, the stored data of the SD card can quickly and due to encryption also safely, transferred to a PC without the need of additional software. As an additional advantage of WebDAV, Port 80 is used, which is generally not blocked by firewalls.

User friendliness and retention of well-known features

Operation of the Memograph M is easy. In the standard version it can be done with the help of the navigator at the front of the device and in the stainless steel version via touch screen. USB keyboard and mouse can be connected directly to the device. Furthermore, the device can easily be set up with the help of the completely new and improved web server. Indication of instantaneous values, instrument health status, remote access, and control of the device are also enabled by the web server.

Besides the described new functions, all important features that are already well known from the previous device are kept in Memograph M RSG45. The process values are indicated on the 7 inch high resolution display, in up to 10 signal groups, with various display options. All the values have tamper-proof recording on the internal memory. This is also optional on the SD card. The security requirements of FDA 21 CFR part 11 are fulfilled. There are several software packages available, including mathematic, tele-alarm, wastewater and storm overflows, batches, and energy. Due to the different software packages and the modular design of the hardware, Memograph M RSG45 can be perfectly adapted to the particular application. Users only pay for what they need.

With the launch of the new Memograph M RSG45, Endress+Hauser is able to offer a state-of-the-art data manager portfolio: The Ecograph T RSG35 as the cost-effective solution for simple applications and the Memograph M RSG45 with cutting edge technology at an excellent price-performance ratio for sophisticated applications. Data managers by Endress+Hauser now offer the right choice for every application.

For more information contact Benjamin Mlangeni, Endress+Hauser, +27 (0) 11 262 8012, [email protected], www.za.endress.com

| Tel: | +27 11 262 8000 |

| Fax: | +27 11 262 8062 |

| Email: | [email protected] |

| www: | www.endress.com |

| Articles: | More information and articles about Endress+Hauser South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved