In 2010, Yokogawa launched its first wireless field products conforming to the ISA100.11a standard and today continues to spearhead the development of industrial wireless technologies.

Recently, the company released a new, large-scale, reliable, next-generation plant-wide field wireless system with the following key features:

• Reliability: reliable high-performance field wireless and redundant technologies.

• Flexibility: flexible architecture supporting the full range, from small to large-scale plants.

• Openness: open ISA100.11a standard allowing third-party field wireless devices to be connected.

Next-generation field wireless systems

Although most field wireless systems are currently installed in relatively small areas, demands are rising to increase the number of monitoring points, covering wider areas, and expanding to process control as well as diagnosis, monitoring and measurement. To respond to these demands, Yokogawa has developed a large-scale, reliable, next-generation plant-wide field wireless system, which can manage up to 500 wireless field devices.

Conventional small field wireless systems are mainly installed as additional monitoring tools in areas with a clear line-of-sight such as tank yards and wastewater treatment facilities. Such systems offer only limited advantages such as improved inventory management, reduced regular visual checking, automated environmental measurement, and reduced wiring costs. In contrast, plant-wide field wireless systems can cover both a large number of measuring points in a small area with a high density of production equipment, as well as the entire plant. This allows customers to set up wireless devices anywhere in their plants and manage data from those devices to improve plant-wide production efficiency.

Several products have been added to the architecture of the new field wireless system including:

• YFGW410 field wireless management station.

• YFGW510 field wireless access point.

• YFGW610 field wireless media converter.

In the new architecture, the YFGW510 serves as an access point and forms the wireless backbone network with the YFGW410 field wireless management station. Therefore, by installing multiple YFGW510 field wireless access points throughout the plant, wireless sub-networks can be built and then connected to each other to create a large-scale, plant-wide field wireless system. The YFGW510 and YFGW410 can communicate via Ethernet, optical Ethernet, wireless LAN, instrumentation cable communication, and so forth, allowing flexible installation in plants. Yokogawa’s YFGW710, the existing all-in-one type field wireless integrated gateway, combines all the functions of access points and wireless management, enabling small wireless systems to be easily installed.

Yokogawa’s field wireless has excellent receiving efficiency with high reliability of the wireless physical layer (Reliable Radio). The technology enables communication within a 600 metre radius, with a standard antenna if there are no obstacles.

Reliability

The reliability of the network layer is enhanced with the following new technologies:

Duocast

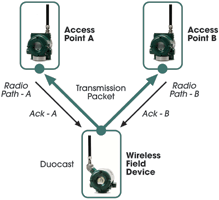

Duocast is a redundancy technology for the wireless path specified in the ISA100.11a standard. In the conventional mesh-topology network, if communication is not established in a path, data is then sent via another path. However, this may affect real-time performance because the data is not sent in the same time slot, but in a later time slot even in the same superframe.

Yokogawa’s Duocast technology simultaneously sends two sets of identical data in the same time slot, and provided either data is successfully transmitted, real-time performance is maintained. Therefore, Duocast is ideal for ensuring the redundancy of mission-critical wireless paths and helps improve reliability while securing low latency (see Figure 1).

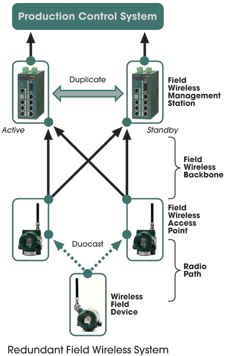

Dual wireless backbone network

The network between the YFGW510 and YFGW410 is called a wireless backbone network. Its redundancy is specified by the ISA100.11a standard to improve the reliability of the network and is achieved by the redundant YFGW410 stations. Either of the dual YFGW410 stations can deal with disconnections and errors of the wireless backbone network, as well as malfunctions of the other YFGW410 stations. One station is set to active and the other to standby and these are connected together via a synchronous communication cable. If a fault is detected in the active YFGW410, the functions and data are quickly routed to the standby YFGW410 to seamlessly continue communication. (see Figure 2).

Further enhancements

The communication quality has been improved with the release of the detachable antenna type model. The extension cable and high-gain antenna can be used with this model. The placement of the antenna can be adjusted with the antenna extension cable without change to the installation of transmitters.

The battery life of the detachable antenna type model has been extended from 1,5 times to 2 times more for a product with low power consumption. The EJX B series wireless differential pressure/pressure transmitter battery will last 10 years with an update time of 30 seconds or five years with a 10 second update. Similarly, the YTA510 wireless temperature transmitter battery will last 10 years with an update time of 10 seconds and eight years with a 5 second update time.

Summary

The flexibility of wireless solutions enables less investment in infrastructure, while providing greater process insights into plant operations where the measurements were previously too difficult or uneconomical to implement. The ISA100.11a’s robust security mechanism provides continuous safety in various system operations.

For more information contact Christie Cronje, Yokogawa South Africa, +27 (0)11 831 6300, [email protected], www.yokogawa.com/za

| Tel: | +27 11 831 6300 |

| Fax: | +27 11 86 411 8144 |

| Email: | [email protected] |

| www: | www.yokogawa.com/za |

| Articles: | More information and articles about Yokogawa South Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved