Datapaq is a leading manufacturer and service provider for temperature profiling systems. It provides some of the industry’s most complete offerings for the monitoring, logging and profiling of temperatures in applications like furnaces and ovens and is trusted by manufacturing industries worldwide to provide rugged, dependable systems for use in harsh and high temperature environments.

Paint curing applications in the automotive industry

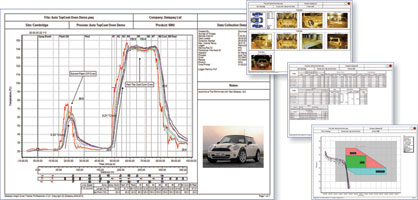

In the car manufacturing industry, automotive paint cure application challenges are overcome by the Oven Tracker XL2 system, developed specifically for the industry to improve paint quality, line productivity and process efficiency.

For successful paint cure, irrespective of the paint chemistry being used, there is a critical need to measure and control the temperature of the car body as it travels through the oven. Today, paint ovens are controlled in a sophisticated fashion via thermocouples located in each zone to give constant feedback on the ambient temperature. Although this temperature data is helpful as it gives an idea of process control from an oven perspective, it does not tell the whole story.

To cure the paint to specification (cure schedule), the critical information required is the peak metal temperature and the time that peak metal temperature is maintained. The control thermocouples in the oven cannot provide this data.

According to Datapaq, oven temperature profiling is the only accurate method by which the oven process can be monitored to determine that the paint cure schedule has been correctly achieved. The oven profiling system is designed in such a way that it is able to travel with the car body through the cure oven, measuring continuously the product temperature at selected locations on the car body. At the end of the process, the collected temperature creates a thermal profile of the product from which the cure schedule can be measured and validated.

One of the biggest challenges of oven profiling in an automotive paint shop is the sheer scale of the operation and time it takes to transfer equipment to and from the QA office to the paint line requiring testing.

Oven Tracker XL2

The Oven Tracker XL2 has been developed with key features that allow sequential testing of multiple ovens without the need to download profile data between runs. The XL2 logger can be programmed to perform multiple runs (up to 10), so that each oven can be tested and its data stored separately in the memory of the data-logger.

Complementing the multiple run operation mode, the user can employ a unique feature called SmartPaq. Prior to the run, the user can program the logger with critical target performance criteria (maximum temperature limit, time at temperature target or acceptable Datapaq value range). The data collected by the data-logger is analysed against these criteria at the end of the run and the logger displays whether the criteria have been achieved or not. The SmartPaq feature makes profile qualification as easy as checking for a green Pass LED, which means the user can move on to the next oven with confidence and without any need to download data. The data can be analysed in full later after all runs are completed. If the LED is red, then there has been a process problem. Knowing this fact as soon as possible is critical to reducing rework, since the root cause of the problem can be identified much earlier in the process.

Datapaq has worked with key automotive manufacturers to develop a barrier technology that allows not just one or two ovens to be tested sequentially, but the complete paint operation from start to finish in one single run. This single pass method is used with a test car, allowing the system to be installed off line.

The test car is then installed onto the paint line after the e-coat dip tank and allowed to run through the entire paint line, as if it was a production car. Completing the run in one operation removes labour (60% labour cost-saving) as the system does not need to be installed and removed for each oven, as it would with a conventional profiling procedure. The thermal barrier is designed to protect the system during the process (including delays) without any risk to the data-logger overheating. The single pass barrier is completely silicone-free, as are all standard Datapaq barriers used in automotive paint operations, and gives protection at 150°C for 13 hours continuously. After the test run, the test car can be moved offline and the data-logger retrieved by the operator at their convenience.

From the single profile technique, a single profile graph with numerous oven peaks is created, but these can be separated easily and efficiently using software tools that allow each paint process to be analysed against its own unique criteria.

To determine whether the process matches the paint supplier’s cure schedule, a variety of analysis tools can be considered. At the simplest level, time at temperature calculations can give an approximation to whether the coating has experienced enough heat to allow the cure reaction to reach completion.

On a more sophisticated level, the Datapaq value index of cure calculation can be employed. The calculation uses the sum of all time and temperature contributions taken from the profile graph to generate a single cure index value. This Datapaq value accurately quantifies total cure over the whole profile.

Consistency is key

A challenge for many automotive paint operations is getting consistency of cure on all areas of the car. In many plants, engineers are working to very tight operating variables. To help with these important criteria, the Insight software can perform an automatic temperature difference analysis to highlight problem areas within the process.

Such data is important to allow identification of the root cause and necessary corrective action. At the end of the day, data reporting and archiving is critical to the certification of automotive processes, whether working ISO 9000, QS9000 or even CQI-12.

The Datapaq Insight system has been developed to allow customisation of the full report generated to include the specific data and information required. If necessary, the archived data can be used to generate SPC charts to show how key parameters (Datapaq values, time at temperature, etc) are changing within time. Within the Insight software, the SPC program automatically produces SPC charts without any need for data export or use of special packages.

Although oven profiling has been used for many years in the automotive coatings industry, it has come a long way from its humble beginnings. Updated technologies from Datapaq now provide a range of benefits that allow the paint shop or production manager to understand, control and optimise oven cure processes with even more accuracy and efficiency. The paint shop manager is now able to maximise the coating quality of the finished product, ensuring customer satisfaction and the efficiency through the complete paint finishing operation.

| Tel: | +27 11 608 1551 |

| Email: | [email protected] |

| www: | www.randci.co.za |

| Articles: | More information and articles about R&C Instrumentation |

© Technews Publishing (Pty) Ltd | All Rights Reserved