Modules 1 and 2 of the Sebokeng Water Care Works (SWCW) have been de-commissioned and prior to the current expansion, module 3 and 4, which have a daily capacity of 30 Ml and 35Ml respectively, had been running above their design limits resulting in the inefficient treatment of sewage effluent. The solution was the addition of another module and the upgrading of the existing scada facilities to the latest technology.

Sebokeng and Evaton are two previously disadvantaged, sprawling residential areas located in the Emfuleni Local Municipality (Sedibeng District Municipality), which is serviced by Metsi-a-Lekoa, the water and sanitation business unit of the same municipality. These areas support a population of 420 000 and consist of approximately 65 000 freestanding housing units in the Vaal Triangle near Vereeniging.

In 2000, Ram-Tec Systems successfully completed a major upgrade, known to Sebokeng Water Care Works as Module 4. Years later, the company was asked to implement the addition to the control system for the new Module 5, which is a 35 Ml/day biological nutrient removal activated sludge unit. The contract for the supply, delivery, installation and configuration of the software for the PLC and scada control system was awarded to Ram-Tec Systems by consulting engineers, Lyon and Partners while the Emfuleni Local Municipality was responsible for implementing the system.

System overview

The module 5 extension included a new inlet works, primary sedimentation works, reactor basin, thickener pump station, screenings facility, clarifiers, chlorination system and a new power monitoring system.

One of the key system requirements was that the treatment of effluent needed to continue uninterrupted even in the event of a catastrophic failure of the control system. Another was to keep Module 4 fully functional while the new system was being commissioned.

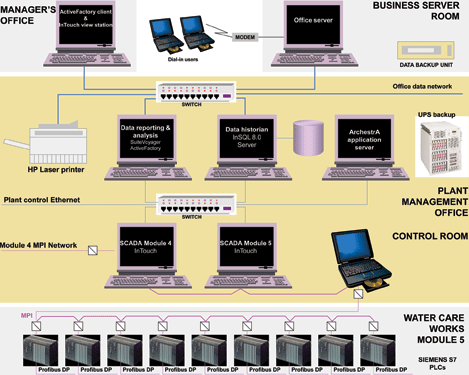

A distributed control system was installed consisting of eight HMI terminals on a Profibus network for local operational control of each separate process (see Figure 1). An MPI fibre-optic network was installed as the common network between all existing and new PLCs as well as for the connection to the main scada system. Fibre-optic cables were chosen to protect against hostile environmental conditions such as lightning while providing error-free communication over long distances. Self-diagnostics on the OLM fibre-optic converters at each PLC made the testing and setting up of the network simple and quick.

All the PLCs are connected to two InTouch scada stations located in a central control room. The scada system is running on an ArchestrA platform with a separate InSQL Server, a separate reporting machine and a separate galaxy repository. ActiveFactory is used as the primary analysis tool and can be accessed remotely if required. The plant manager is running an InTouch view node from his office. The existing Module 4 was incorporated into the system thereby providing an effective way of monitoring the entire plant, which is spread over a large geographic area.

Motor control centres (MCCs) and electricity consumption monitoring

In the MCCs, various combinations of Siemens Simocodes and VSDs were installed which share the same Profibus network as the OP27. Additionally, a Siemens ET200S motor start system was installed in the field to control a custom-designed oxygen utilisation rate sampler for the aerator basin. The ET200S communicates with the chlorination PLC via Profibus.

Some of the PLCs also have Profibus DP field instruments connected to them, namely Endress+Hauser flow meters, suspended solids meters, dissolved oxygen meters and level transmitters. The primary sedimentation tank’s screens and the screenings facility also have Endress+Hauser level transmitters running on Profibus DP/PA.

Each MCC also has either one or two (depending if there are separate essential and non essential services) Socomecs on the Profibus network. The Socomec provides energy consumption information such as voltage, current, power, power factor, etc. This information is displayed on the scada systems and helps to determine the electricity costs. The main incoming substation has Socomecs on each of the feeders, which communicate to a dedicated S7-300 sharing the same network as the other PLCs.

Overcoming the challenges

The entire Module 4 and Module 5 control system was developed in the allocated project period in spite of some difficulties. The distributed nature of the plant over a sizeable geographical area presented unique challenges, hence the use of fibre-optic cables for reliable communications. It would also have been easy to revert to the traditional thinking of individual modules and lose sight of the fact that they are all part of the same facility and should be treated as such. To this end, ArchestrA’s ‘galaxy’ and single namespace concept, helped to pull it all together.

Another approach which was of great help was the ability to use the technology available in the field instruments to assist with diagnostics and fault finding. The open networks and standard industrial protocols made it easier to integrate the different supplier platforms. However, the large amount of information supplied by the intelligent devices had to be carefully filtered and collated in order not to overwhelm the personnel required to act on it.

With its comprehensive real-time reporting facilities, plant-wide centralised control, easy access to operational information and defined standards, the Sebokeng Water Care Works control system is geared for fast and cost-effective expansion as well as efficient operation.

For more information contact Jaco Markwat, Wonderware Southern Africa, 0861 WONDER, [email protected], www.wonderware.co.za

| Tel: | +27 11 548 9960 |

| Email: | [email protected] |

| www: | www.profiafrica.co.za |

| Articles: | More information and articles about PI SA (PROFIBUS & PROFINET SA) |

© Technews Publishing (Pty) Ltd | All Rights Reserved