“Hello, could I talk to a person in your organisation, or in your client base, who has expertise in the application of instrumentation and control to the problem of acid mine drainage?”

While the problem of acid mine drainage (AMD) is a hot-topic in the daily press, polling a response from key suppliers and system integrators in the South African instrumentation industry reveals that investment in the monitoring and control of AMD is at a low level. Our health and environment are under threat but perhaps there is a silver lining of business opportunities in the offing for our industry.

What is AMD?

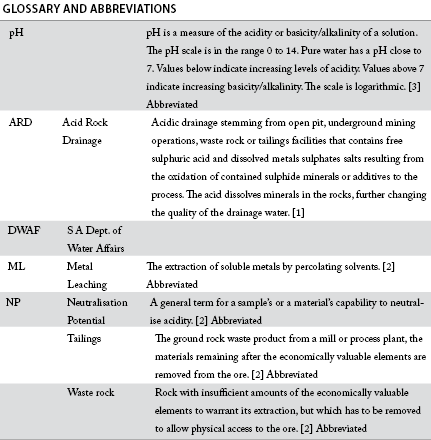

Acid drainage (AD) or acid rock drainage (ARD) is the flow of acidic water from a source. Where that source is a mine then the phenomenon is referred to as acid mine drainage.

AMD is often associated with abandoned mine workings where mining has progressed below the water table and pumping has been discontinued. Surface run-off water, which may already be contaminated after percolating through waste rock and tailings, finds its way into mine workings until they are filled to a level where they start to decant into aquifers at which stage naturally occurring compounds dissolved in the mine water contaminate natural ground water resources. These compounds are often metal sulphides including sulphides of copper, iron, nickel and zinc.

In the presence of air and water, chemical reactions occur which result in the release of hydrogen (H+) ions, sulphates and dissolved metal ions, all of which are detrimental to water consumers and the environment.

Environmental consequences of AD

Contaminated ground water ultimately finds its way into river systems, dams and boreholes where the acidity and metal content cause harm through several different mechanisms:

* Many plants, fish and animals are unable to survive below certain pH levels and contaminated ecosystems may become devoid of life.

* As the pH of the low pH contaminated water is raised back above 3 through dilution with more neutral water sources, the metals precipitate out leaving a crust of metal-rich residue on streambeds, riverbeds and dams. This impacts the lifecycles of all members of the aquatic and riverine ecosystem, including insects, crustaceans and their predators (frogs, birds and mammals).

* The raised levels of metals can become toxic to living organisms.

Whose problem is AD?

Putting the sensationalism of the popular press to one side, readers should be aware that AD is:

* Not solely a mining problem.

* Not just a chemical problem.

* Not a uniquely South African problem.

* A problem for current and future generations.

It is not solely a mining problem because the processes involved can occur anywhere that ground is disturbed (for example highway construction) and there are particular naturally occurring compounds in that ground. AMD is not exclusively associated with deep mines: open pit and strip mines, dumps and tailings dams may also be sources of AD. And the problem is not only associated with the mining of gold and platinum – the mechanisms of sulphide breakdown are also commonly found in mining coal, iron, zinc, nickel and even more so in copper mining.

It is not just a chemical problem because the activity of microorganisms can create a spiral of reactions where pH is driven to as low as 1. The complex breakdown of the sulphides and the release of hydrogen and metal ions are referred to as a biogeochemical process – recognising that biological, geological and chemical processes all play a part.

It is not a uniquely South African problem and is proving to be a headache to governments, environmentalists, mining and construction industries in Third World and First World economies.

It may be a problem in perpetuity. According to Mining Watch Canada, the Equity Silver mine near Houston will require treatment for AMD for at least the next 500 years and Roman mine sites in Great Britain continue to generate AMD 2000 years after they were abandoned.

An environmental mind set

Around the world, the higher levels of awareness of the AD problem and a greater understanding of the causative mechanisms have led to the introduction of increasingly stringent legislation and changed mindsets in government and the mining industry.

Leaders include Australia, Canada, the European Union and USA. Perhaps one of the most aptly named programmes is the Canadian Mine Environmental Neutral Drainage (MEND) initiative.

South Africa’s Department of Water Affairs has published a comprehensive series of Best Practice Guidelines for Water Resource Protection in the SA Mining Industry.

Environmental cost issues have really been the driving force behind engineers and manufacturers being urged to consider energy balances in every part of their design so process engineers, mining engineers and metallurgists need to be considering the environment and potential waste streams in every part of their designs.

Every discipline needs to adopt an environmental mindset.

South African status

Some press reports may have created the impression that nothing is being done concerning AMD in South Africa. While it is true that we do not yet have a comprehensively integrated response involving government ministries, mining companies and potential technology suppliers, there is more than just hot air being generated:

* Research organisations such as the CSIR and Mintek (SAVMIN process) have prototyped viable pilot plants for the treatment of AMD streams.

* Anglo Thermal Coal in partnership with BHP Billiton Energy Coal South Africa and the Emalahleni Municipality built and put into operation in 2007 a R300m plant that desalinates 25 megalitres per day of water from underground workings.

* In its August 17 released 2010 Interim Report to the Stock Exchange News Service (SENS) Central Rand Gold Limited noted that “... the Minister of the South African Department of Water Affairs, Minister Buyelwa Sonjica, ... confirmed that the South African government recognised that as 70% of the mining area in the Witwatersrand district is currently ownerless the liability to resolve the AMD problem would reside with the State, requiring a contribution of approximately R145 million. The remaining 30% liability would be funded by existing active mining operations in the area. To limit the extent that the water table will rise above the 400 mbs level, the Company has placed an order for the submersible pumps, which are the project’s longest lead item. The initial payment of R10 million will form part of CRG’s total committed contribution of R36 million.”

* On 6 September the Minister announced that cabinet has appointed an inter-ministerial committee to address the current challenges of AMD. The committee has already had its first meeting.

Instrumentation opportunities

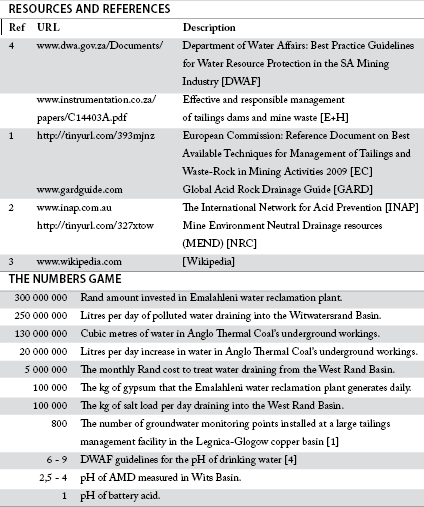

To find a site-specific solution for AMD it is important to know the actual source ie, where the sulphide breakdown is occurring. This will be situational and may vary from site to site. There are more than 800 groundwater monitoring points installed at a large tailings management facility in the Legnica-Glogow copper basin.

To be able to fairly apportion liability, regulators need to know subterranean flows – directions and flow rates and also to record volumes and qualities of waste discharged into catchment areas.

The volumes of water requiring pumping and treating over extended periods – decades, if not centuries – are mind boggling (See below 'The numbers game'). But from an instrumentation perspective it is the stuff of dreams. Let us see... How many flowmeters, pH transmitters, wireless network points, VSDs ... will be needed to monitor and control these gargantuan flows?

Early days

While it is early days, we must hope that the pressures being applied by the environmental lobby will result in positive action and higher levels of investment by both government and industry.

The desired outcome should be relative stability of underground aquifers and treatment of harmful acid drainage ensuring that pH levels are suitable for water re-use or discharge into river systems and that levels of dissolved metals and radioactive components are reduced to accepted public safety norms.

About the author

Andrew Ashton has electrical, mechanical and business qualifications and has been active in automation and process control since the early 1980s. Since 1991 he has headed up a company that has developed formulation management systems for the food, pharmaceutical and chemical manufacturing industries and

manufacturing solutions involving the integration of various communication technologies and databases. Developed systems address issues around

traceability, systems integration, manufacturing efficiency and effectiveness. Andrew is a contributing editor for SA Instrumentation and Control.

| Tel: | +27 31 764 0593 |

| Email: | jane@technews.co.za |

| www: | www.technews.co.za |

| Articles: | More information and articles about Technews Publishing (SA Instrumentation & Control) |

© Technews Publishing (Pty) Ltd | All Rights Reserved