The exponential growth of Amatola Water’s radio telemetry system from 16 outstations to 96 meant that the East London-based state owned entity required a monitoring system that could meet its growing needs. Amatola Water chose an Adroit scada system to fulfil its objectives.

Amatola Water is a bulk, purified water distributor. Covering an area from East London to the Fish River (approximately 6500 square km), its main customers are Amatola District Municipality and Buffalo City Municipality.

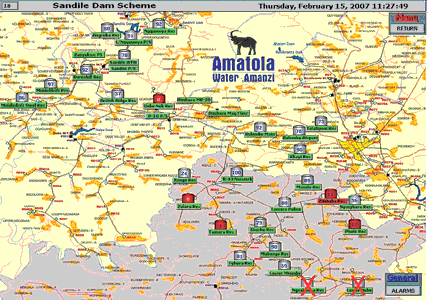

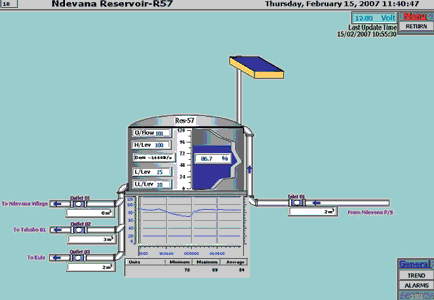

The reticulation system consists of three large plants, another four smaller plants, with the balance of the outstations being reservoirs that require monitoring. The scada actively monitors plant operation and reservoir levels for the 96 outstations, and reports back via radio telemetry to a central station running Adroit Version 6.

The telemetry system started its life in the mid 1980s when the then Ciskei Government purchased a basic Motorola Intrac 2000 system with four outstations reporting to a hardware master station. Later, a DOS-based Motorola scada package and more outstations were added.

This was updated to a Windows 95-based system (Fix) before re-incorporation with the Dept. of Water Affairs in 1994. In 1997/98 the Amatola Water Board was established and the whole monitoring system was upgraded to the current hardware configuration, and FactoryLink scada software.

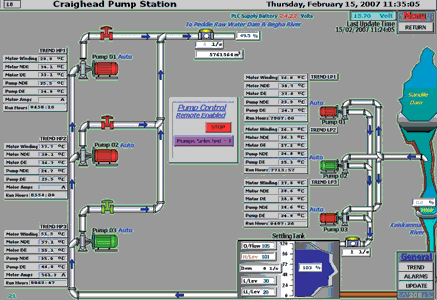

The six major pump stations have PLC controlled MC panels. The telemetry RTU is connected to the PLC via a serial interface using Modbus protocol and provides the ability to monitor all the inputs as well as providing the facility for remote modifications of certain measuring and controlling parameters within the PLC.

KISS

In 2002 it was decided to change to the Adroit scada system. Telemetry experts and system integrators, SSE, created the basic graphics of components such as the shape of the reservoirs and screen layouts for the original system. They were also called in to assist with the migration to Adroit. Amatola's radio and telemetry senior technician, Gerry Roux, has since then taken the original overview graphics, and using an area map obtained from the GIS (geographic information system) division created a background for the mimic screens that provides an accurate account of where the outstations are located.

Amatola Water has a 5000 tag Adroit licence, but are only using about 3000 of those. "By choice we are only using about 25% of Adroit's potential. I believe in the KISS principle of simplicity," says Roux.

Unlike the complex architecture of an average manufacturing plant, the limitations of radio telemetry on hard wiring ensure that the solutions are kept simple and effective. "The most complicated part of the system, is explaining to non-technical people that they are not viewing the operations in realtime," jokes Roux, who has added an onscreen time stamp, scripted by Adroit, to assist with this.

The scada is primarily used for monitoring the status of the reservoirs and major pump stations. Amatola has recently established a central control room where a PC workstation, (with Adroit remote view software is linked to the main Adroit server), provides details of the entire operations area.

Each major plant also has a PC, with Adroit remote view software, linked to the main Adroit server via the IT wide area network (WAN). Matching the system to the skills levels of its staff, Amatola has designed the system in such a way that remote PCs can only view the portion of the water reticulation that their area covers. Users have limited access to system commands eg, some stations having pump stop/start command capability.

Where automatic control is required ie, stopping and starting of pumps via level control, this is handled by the telemetry's programmable RTUs, which are configured in a standalone architecture. The OPC interface does allow for the RTUs to be programmed remotely, thus level control parameters can be changed on request.

The Adroit interface only provides operators with the ability to stop or start some of the major pumps, as well as access to alarm screens and pre-defined trend graphs.

The status of outstation alarms are depicted on screen with green, red, orange and yellow as well as flashing colour symbols to show critical water levels.

Plant operators also rely on Adroit's trending function to see what happens overnight and on weekends. Some of the managers also have a view-only node of the plant's operations from their offices to facilitate reporting and business decision-making.

At the major plants, the Adroit SCADA monitors flow with data collected from the Magflow meters. Totals, turbidity meters, and sampling meters are amongst those used for rudimentary data display purposes.

Amatola's Radio and Telemetry workshop division consists of two people. "Many people think that once you have installed a system it takes care of itself, but radio telemetry systems need constant maintenance," says Roux. Roux has been involved with radio telemetry since 1982. His extensive experience, coupled with Adroit's easy-to-use scada package, enabled Gerry to do most of the outstation set-up, scada configuration, and the intricate mimic backgrounds.

| Tel: | +27 11 658 8100 |

| Fax: | +27 11 658 8101 |

| Email: | info@adroit.co.za |

| www: | www.adroit.co.za |

| Articles: | More information and articles about Adroit Technologies |

© Technews Publishing (Pty) Ltd | All Rights Reserved