Adroit has been selected as the scada of choice for the Modikwa Platinum Concentrator. Modikwa is a 200 kTPM concentrator with controlled by three Siemens S7-400 'Hot-Standby' PLCs. State-of-the-art 'Profibus', 'Industrial Ethernet' and ASI bus systems have been used extensively, eliminating the need for any conventional I/O.

The plant has a total of 580 drives all equipped with the Siemens Simocode. The flotation plant has a total of 70 flotation cells that are each equipped with level control and airflow control loops. The Adroit scada system is 'dual redundant' Active Cluster with automatic switchover in the event of a failure of any component. Full redundancy on the PLC and the scada was essential due to nature of the process.

Extensive use has been made of Adroit's indirect addressing functionality to minimise the network traffic. This has resulted in screen update times of less than one second. Template mimic and trend facilities of Adroit further reduced the number of windows and helped in creating a uniform look and feel to all areas of the plant. Due to the large amount of data available from the 'Profibus' instrumentation it has been possible to build in a large amount of diagnostic information and make this available to the operator via the Adroit interface. Johan Kuntz from iControl, the primary scada engineer, has focused heavily on the maintainability of the system. This led to some product development taking place - allowing mouse movement to drill down for more information on specific mimic items like faceplates etc.

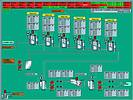

The quality of the graphics available as a standard feature with the Adroit system (see pictures) has resulted in crisp clean displays that look highly professional with minimal programming effort. "The graphics package must certainly be the benchmark for any control system," was a comment made by Nolan Virtue, the consultant on this project.

An SQL server has been used for all historical, alarm and event recording. A total of 25 000 tags are being logged at various intervals to enable comprehensive production, diagnostic and maintenance reporting. Adroit's native interface to ODBC compliant databases (DbAccess agent) allows seamless integration to the SQL backend. In addition ad hoc queries can be performed to extract specific information.

Using the OPC compatibility it has been possible to interface the Adroit with other 3rd party packages for advanced control such as a Minovex Expert System, Mintek Floatstar system, Malvern Particle Size Monitor as well as CCTV.

A point worth noting is that the complete scada configuration was performed over a four-month period by just one programmer.

For more information contact: Paul Geng, Adroit Technologies, tel: 011 781 3513, e-mail: [email protected], website: www.adroit.co.za

| Tel: | +27 11 658 8100 |

| Fax: | +27 11 658 8101 |

| Email: | [email protected] |

| www: | www.adroit.co.za |

| Articles: | More information and articles about Adroit Technologies |

© Technews Publishing (Pty) Ltd | All Rights Reserved