A project for developing the use of wave energy for the generation of electricity features AC drives from Control Techniques. The drives are a key feature in wave-

power projects around Europe.

Inverness-based Wavegen, part of Voith Siemens Hydro Power Generation, is a wave energy company dedicated to the development of marine renewable energy technology.

On the Isle of Islay, off the west coast of Scotland, Wavegen has an inclined oscillating water column (OWC) generating facility that is used both for generating power and for testing new designs of Wells turbine generators.

Two 250 kW counter-rotating turbines have been generating power for several years at this ‘Limpet’ (land installed marine powered energy transformer) unit, which utilises the power of a surge-dominated wave field adjacent to the shore. The water depth at the entrance to the OWC is typically seven metres and the air chamber is designed to maximise the capture of wave energy and power output.

Now, one of the turbines has been removed to provide Wavegen with a test-bed for a new design of small turbogenerator that can be incorporated into breakwaters, coastal defences, land reclamation, port walls and community power schemes. These are a fifth generation of Wells generators and incorporate all of the learning and cost-reduction gained from development and practical operation of the Limpet plant.

“It was crucial that we selected the right drive system to accommodate both our changing needs during the development process and the requirements of future customers of these breakwater generators,” explained Dr Tom Heath, engineering manager at Wavegen. “We considered five drives suppliers and Control Techniques proved to be a clear choice for several reasons,” he says. “The over-riding factor was the facility to program the drives in a high level language. It proved to be very easy to adapt the SyptPro control language used by Control Techniques – and their willingness to give us total access to the drive functions proved crucial.”

Two 32 kW Unidrive SP drives are fitted; one to control the turbine speed, the second running in regenerative mode to feed AC power to the grid. Both are fitted with SM-applications modules to provide powerful on-board programming of the system and the first, additionally, has an Ethernet communications module. Because of the high-level of I/O required – some 20 channels, monitoring temperature, speed, chamber pressure and pressure drop across the butterfly valve etc – additional I/O is provided locally with a Beckhoff unit.

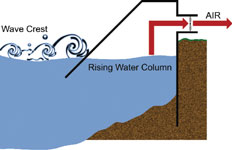

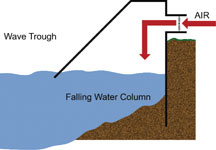

Wave motion drives air up (or down) the inclined water column as can be seen in the diagrams. In turn this drives the bi-directional flow, uni-directional Wells turbine that runs at up to 4000 rpm and which is connected to an induction generator.

Pressure transducers in the chamber feed the RMS pressure back to an SM-applications module via the Beckhoff unit. The program calculates the optimum speed for the turbine and the unit can be started. The Unidrive SP motors up the turbine to the optimum speed and then switches from motoring to generating mode, allowing the low-inertia turbine to drive free, with the air pressure, but limiting its maximum speed. Then, using a five-minute moving average of the chamber air-pressure, the maximum turbine speed is adjusted every 30 seconds to give an optimum output from the Wells turbine installation.

Normally, the Wells turbine runs 24 hours a day in fully automatic mode, except when very high sea states require throttling back by using the butterfly valve.

“The Unidrive SP AC drives, with their Ethernet connectivity, have proved ideal during our development phase. In the future, this will be equally important so that we can provide our clients with technical support via the Internet,” concludes Heath.

For more information contact Bill Tedd, Control Techniques, +27 (0)11 462 1740, [email protected], www.controltechniques.com

| Tel: | +27 11 462 1740 |

| Fax: | +27 11 462 1941 |

| Email: | [email protected] |

| www: | www.controltechniques.com |

| Articles: | More information and articles about Nidec Control Techniques |

© Technews Publishing (Pty) Ltd | All Rights Reserved