In March of this year, the SABS released an updated list of published standards, which included the SANS 12100: 2013 standard on the safety of machinery. The release of this standard has a significant impact on machine safety in South Africa.

So what is SANS 12100: 2013, and why should we be interested in what it has to say?

SANS 12100: 2013 is a local adoption of the European ISO 12100:2010 standard on 'Safety of machinery', which governs 'General principles for design – Risk assessment and risk reduction'.

Up until this point, the requirements governing machine safety in South Africa have been a pretty vague affair, based on the premise that a reasonable person should make a reasonable attempt to make his machine reasonably safe, more-or-less. The Driven Machinery Regulations (DMR) does mention certain specific criteria, such as the need for a guard (fixed, moving, presence sensing, etc) where the opening to a cutting or pressing machine is greater than 10 mm, but the decision of what to use, where to use it, how to use it and who should be responsible for the installation, appears largely left up to the 'reasonable person'.

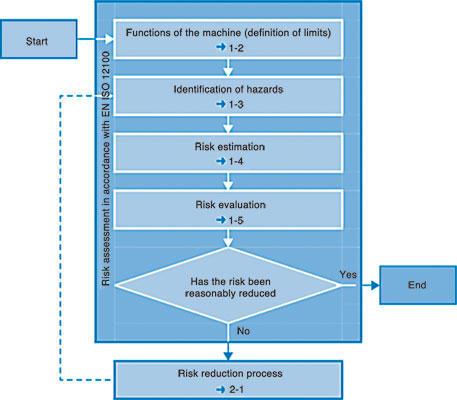

The process of risk reduction, according to SANS 12100

According to the standard, the onus of risk reduction lies with the machine designer firstly. This means that machine safety must be addressed in the design stages of the machine, before manufacturing has begun. It is up to the designer to determine the limits of the machine, or in other words: the expected lifespan of the machine, where the machine will be used, what it will be used for, how it will be used, the possibility of misuse, and how the misuse might take place. This must be done for each phase of the lifecycle of the machine. So, we would need to investigate these various factors during installation, normal operation, unscheduled stopping, cleaning, maintenance, etc.

Once the designer has determined the limits of the machine, they must then identify all hazards and hazardous situations that can arise during use of the machine in the different phases. At this point a risk estimation is done, based on how severely the machine operator might be harmed due to the hazard and how often or how long they are exposed to the hazard, how often the hazardous situation is expected to occur, and the possibility of avoiding or limiting exposure to that hazard.

Now the designer must use the information from the risk estimation to carry out a risk evaluation to 'grade' the levels of risk which will act as a guide for the actions they must take for each hazard.

First prize would be simply to design the hazard away. For instance, if a large rotating gear could catch someone and hurt them, but it can easily be contained inside a fixed housing, then that is what should be done. If the hazard cannot be designed out of the system, then one must look at appropriate safeguarding measures. If everything has been done with regards to the above, but there are still unresolved safety issues, then measures like specialised training for the operators, comprehensive operating procedures etc., must be considered.

Links to ISO and IEC standards

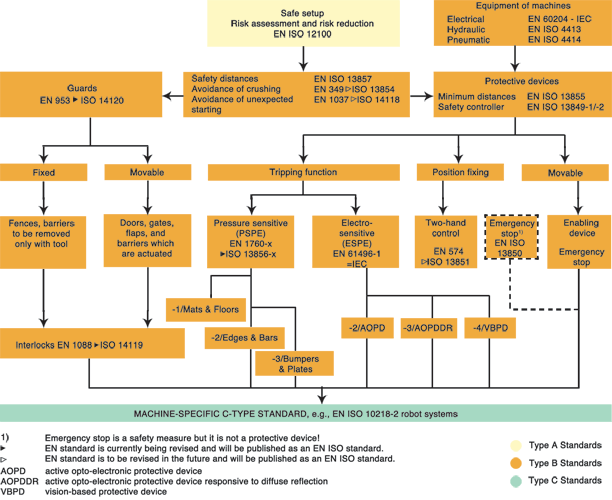

Important to note is that the document makes reference to a number of IEC and ISO standards, including ISO 14119, ISO 14120, ISO 13849-1:2006, IEC 62046 and ISO 13855, amongst others. What this tells us is that we can no longer simply identify a part of the machine as being dangerous and place some kind of (home-made?) guard before the dangerous area, and be satisfied that we have taken reasonable precautions.

We are now expected to follow all the requirements of risk reduction according to SANS 12100: 2013, and based upon our findings, we have to implement the correct safety rated protective measures, in the correct positioning, and have them connected to the safety related part of the control system in the correct way.

It seems very complicated

With the adoption of ISO 12100: 2010 as our SANS 12100: 2013, we now have the opportunity to make use of the best practice methods of machine safety used in Europe and most of the world. For example, rather than reinventing the safety system on a machine one could look at the available type-B and C standards for more specific applications and machines, where:

• Type-A standards cover basic concepts and principles for design of machinery (like SANS 12100).

• Type-B standards are generic standards covering general requirements for safety equipment that can be used on different types of machinery (e.g. EN ISO 13855).

• Type-C standards define detailed safety requirements for specific types of machines (e.g. EN ISO 10218-2).

As mentioned above, type-C standards are usually comprehensive and explain clearly what safety equipment is required where and how it should be integrated and used. So by following type-C standards especially, one can be confident of compliance with the relevant safety requirements. This also removes guesswork from the process, as well as offering an easy explanation of the decision to use safety components – in case an explanation is required.

But it’s actually not too bad

At first glance, the publication of SANS 12100: 2013 might seem like it brings in a mountain of extra work for those who have to decide on the use of safety equipment. In reality though, unless one is involved in the design of a completely new and unique machine, most of the work has already been done.

There are a number of resources available online, one of the best ones being the 'Guide for Safe Machinery' available for free download from www.mysick.com. Additionally, software packages like SISTEMA (Safety Integrity Software Tool for the Evaluation of Machine Applications) offer a standardised system that helps lead one through the process of selecting the correct safety equipment for an application. SISTEMA is available for free from www.dguv.de.

Most safety equipment manufacturers offer their component libraries for free download as well. Then, the software will show, for example, that a SIL3 /PL e light curtain must be used, and one can see the recommended components from the various suppliers.

This means that one simply needs to find the relevant standard for the machine, follow the steps and the instructions, and be secure in the knowledge of world class compliance.

For more information contact Stephen Eltze, SICK Automation SA, +27 (0)11 472 3733, stephen.eltze@sickautomation.co.za, www.sickautomation.co.za

| Tel: | +27 10 060 0550 |

| Fax: | +27 86 598 7915 |

| Email: | info@sickautomation.co.za |

| www: | www.sick.com/za/en/ |

| Articles: | More information and articles about SICK Automation Southern Africa |

© Technews Publishing (Pty) Ltd | All Rights Reserved