Process knowledge is valuable, but without measurement there is no accurate knowledge, only speculation. Companies are increasingly being forced to measure process variables that are difficult to reach and expensive to support. This can be due to environmental and social obligations, greater needs for data on upstream and/or downstream water influences, distances between operational sites and water sources, increasing complexity of pipeline management techniques, and product transfer requirements. Distance, harsh environments and absence of power are just a few of the hurdles faced. With operational efficiency as the primary goal, the deployment of self-powered wireless instrumentation still needs to make economic sense from an installation and maintenance perspective.

In light of the above, Schneider Electric acquired the Accutech range of products a few years ago. With a wide range of available instruments for temperature, pressure, flow, level and more, Accutech instrumentation is suited to many industrial applications including:

• Oil and gas.

• Pipeline instrumentation.

• Remote plant applications in water and wastewater.

Accutech field instruments are ideal solutions in that they are:

• Easy to install, configure and maintain.

• Battery powered with long life (target 5 years).

• Communicate over appreciable distances even in the presence of obstructions.

• Tolerant to noise and interference.

• Suitable for use in harsh environmental conditions.

• Certified for operation in hazardous environments.

• Available with a wide range of sensors.

Flexible wireless communication

Accutech networks use 2,4 GHz licence-free, frequency-hopping, spread-spectrum radios, offering ranges of up to 1 km using standard integrated antennas. Extended-reach options include external directional antennas and configuration with a long-haul data radio that offers 256-bit AES encryption.

Easily configured, highly scalable

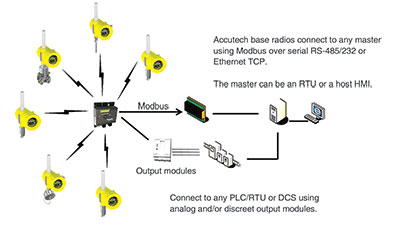

Each Accutech base radio can support 100 field instruments with up to

1 sec sampling on instruments: 256-base radios can coexist for extended scalability. Push-button configuration and simple link test features allow entire networks to be deployed in hours.

Ease of use and low maintenance

Standard Accutech field units include a single D-cell lithium-thionyl battery that offers up to ten years of service, depending on data rates and battery options. Advance notification provides indication before a new field-replaceable battery is required.

ROI and efficiency improvement without compromising safety

Engineered for challenging applications, Accutech networks help to reduce costs and patch holes in any operational data monitoring network.

• Reduced installation costs: reduced cabling, trenching, and conduit costs. Self-powered, means no regenerative power systems.

• Increased productivity: monitoring of process variables that was not possible before.

• Quick configuration, instant connectivity, and minimal maintenance.

• Safety: integrated field units tested for harsh locations enable data point monitoring in tough environments.

Certified and durable

With NEMA4X packaging, Accutech wireless products are designed for demanding applications and are certified CSA Class 1, Div 1 and ATEX/IECex (-ai and -d). A push- button interface enables configuration in harsh environments.

Configure and monitor from base radio

Accutech manager configuration and management software provides a user-friendly commissioning interface for Accutech networks, offering remote configuration and firmware upgrades, enhanced diagnostics, field unit authentication to base radio and trending/data collection.

Take ownership of field instrument networks

Installation of a complete wireless instrument network is easy using Accutech instruments with push-button configuration, integrated link tests, and rugged compact designs. Dependable, self-powered, spread-spectrum radios provide effective network connectivity and long-term service. Tested for use in harsh locations, Accutech field instruments can function in extreme environments of temperature and humidity and are supplied with a threeyear warranty.

For more information contact Gary Bantich, EOH, +27 (0)87 803 9767, [email protected], www.eoh-pas.co.za

| Tel: | +27 11 607 8100 |

| Email: | [email protected] |

| www: | www.di-pas.co.za |

| Articles: | More information and articles about Digitial Industries - Process Automation Solutions |

© Technews Publishing (Pty) Ltd | All Rights Reserved