Rockwell Automation continues to develop its scalable MES applications to allow operations to configure their environment without programming, add more applications, increase DCS process system integration, and expand deployment options. A new suite of capabilities improves functionality across its portfolio of scalable MES applications based on the FactoryTalk ProductionCentre platform. The portfolio includes FactoryTalk Production, FactoryTalk Performance, FactoryTalk Quality and soon FactoryTalk Warehouse applications.

“We are delivering on the promised improvements in usability and flexibility, while adding entirely new applications,” said Christo Buys, business manager for control systems, Rockwell Automation sub-Saharan Africa. “Our modular MES applications are getting easier to deploy and use, with more guided and graphical configuration versus traditional MES which required expertise from several disciplines to implement. “We are also investing in new delivery options, manufacturers will soon be able to purchase SaaS and cloud-based versions of our scalable FactoryTalk MES applications.”

New benefits

Improved user experience

The latest updates to FactoryTalk Production, FactoryTalk Performance and FactoryTalk Quality applications provide a simplified, visual drag-and-drop tool to build new workflows with no coding needed. This means product changeovers can happen faster and allow more flexibility for new product introductions.

The FactoryTalk Quality application now also includes user-friendly intuitive widgets. Based on choices made in setup, the application recommends pre-configured visual widgets, such as gauges or historical data charts, speeding time-to-value and reducing the cost of quality-management efforts.

New FactoryTalk Warehouse application

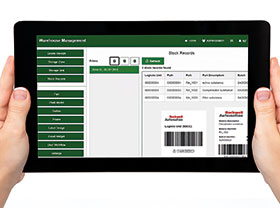

Plant operations often require fast and accurate tracking of material movement and stock information. The latest MES application, FactoryTalk Warehouse, streamlines warehouse logistics to allow fast, precise inventory management and tracking capabilities from goods receipt through stock records and goods issuing.

Improved insight and control benefit manufacturers looking to manage raw material lots, palette load tracking and work-in-progress inventory – all synchronised with the company ERP system. With this information at their fingertips, personnel can manage material levels in near real-time, including forward and backward product genealogy. The FactoryTalk Warehouse application is scalable to fit individual deployment needs.

Increased integration for process applications

An expanded, out-the-box integration tool in the FactoryTalk ProductionCentre MES application portfolio gives users access to more production data across systems, greatly reducing the barrier to entry for connected and smart manufacturing. Enterprise Integration Hub (EIHub) software creates a common connectivity method for enterprise applications and external IT systems. The application reviews incoming information from one system and transforms it into the proper format and template for the receiving system. It also verifies information receipt or sends alerts for transmission failures to streamline data translation across a Connected Enterprise.

Using EIHub, process manufacturers can seamlessly connect FactoryTalk MES applications, including their DCS, LIMS, QMS, PLM or CMMS systems and other databases. Through this vendor-agnostic integration, operators can transport batch-reporting parameters, GMP critical alarms for ‘review by exception,’ and consumption, production and order-completion data. Pre-configured value packs in EIHub software also offer increased productivity for the discrete, automotive and pharmaceutical industries.

Expanded delivery options

Scalable MES applications are cloud-enabled, supporting centralised deployments in private, public and hybrid configurations. Rockwell Automation provides infrastructure-as-a-service offerings today via preconfigured and managed industrial data centres and will soon provide SaaS offerings via the FactoryTalk Cloud platform.

For more information contact Christo Buys, Rockwell Automation, +27 (0)11 654 9700, cbuys@ra.rockwell.com, www.rockwellautomation.co.za

| Tel: | +27 11 654 9700 |

| Fax: | +27 11 654 9702 |

| Email: | mjunius@rockwellautomation.com |

| www: | www.rockwellautomation.co.za |

| Articles: | More information and articles about Rockwell Automation |

© Technews Publishing (Pty) Ltd | All Rights Reserved