Seeing the words ‘deviation matching’ as part of a control philosophy might let the reader’s mind wander toward compressor control, and specifically load balancing, as that is where the term is so often used. Here however, this familiar concept was applied in a novel manner to achieve pressure override control of a liquid header, an application very far removed from compressor control.

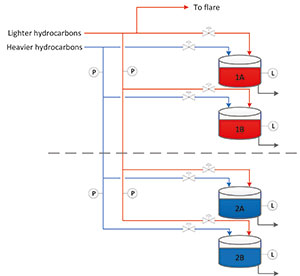

The process layout is illustrated. There is a feed of lighter and heavier hydrocarbons into the respective headers, from which the material can flow into any of the four buffer drums shown. The control objective is preferential feeding of lighter hydrocarbons into the buffer drums labelled 1A and 1B, while feeding heavier hydrocarbons into the buffer drums labelled 2A and 2B. This should happen with buffer drum level and header pressure protection in place.

The handles for material distribution are the flows of lighter and heavier material into each buffer drum. The basis for preferentially sending lighter material to the 1A/1B side is to stagger the level controller targets, such that lighter material is taken into the drum while heavier material is backed out when enough feed is available. When not enough light material is available, heavies are taken in for level protection. On the 2A/2B side the opposite is true. The control problem is made more difficult owing to the fact that availability of feed is variable. The flows out of the buffer drums are also variable. The level control problem is therefore well defined, and through correct manipulation of the flows into each buffer drum, the level control problem is relatively easy to solve.

Pressure protection

The problem of pressure protection is however more difficult. Generally one would expect P1 and P3 to be equal (and similarly P2 and P4 should also be equal). There is however a large distance between the buffer drums (highlighted by the dashed line in the figure), such that pressure losses in the lines become significant. There are also various piping bends, check valves, and other equipment in the lines, which all make the pressures read different values, and which also vary dynamically (i.e. one cannot assume that the difference between P1 and P3 is constant, even though these pressures are related).

In general one would like to base the pressure overrides on a specific header from a single measurement. For example, if P1 and P3 were equal, one might use P1 to cut back on all the flows of heavier hydrocarbons when the pressure drops. A uniform cutback is desired to ensure that feed is not cut back on one side, while it is increased on the other, and vice versa. In such a scenario the control valves are colloquially said to be fighting. In this case, even though P1 and P3 are related, they are not the same, and the standard pressure override solution does not work. The problem is aggravated by the absence of hard-wired electrical signals from the 1A/1B side to the 2A/2B side. Communication does exist between the sides, but transferring and duplicating valve openings cannot happen directly as the communication reliability cannot be guaranteed.

Pressure overrides operate with similar deviations

Conceptually, when performing compressor load balancing one monitors the difference between the current operating point and the surge point, which may be referred to as the deviation (i.e. the current distance from the surge line). Load balancing is achieved when all compressors operate with similar deviations. When performing pressure override control, the operating point can similarly be characterised based on the distance from the pressure override limit (i.e. the current distance from the limit). For the pressure override, the deviation is the difference between the override limit and the current pressure reading. Load balancing in the pressure override scenario happens when the pressure overrides operate with similar deviations.

When pressure override deviations are matched, the underlying PID controllers (with the same tuning) will act in the same direction, and will not fight each other. This is therefore a novel way in which to achieve coordination between the pressure overrides without having to use the same process reading (e.g. only P1). This application does require transmitting the pressure readings and override setpoints to achieve the coordination. When the communication fails however, the pressure overrides are not moved, and pressure protection still exists (the valves will still move on both sides).

The end result of this control installation was that material could preferentially be routed to the desired buffer drums, while maintaining level and pressure protection through coordinated overrides.

For more information contact Johan Maritz, SAIMC Secunda branch, +27 (0)82 856 3865, johanmaritz260@gmail.com, www.saimc.co.za

| Tel: | +27 11 312 2445 |

| Email: | ina@saimc.co.za |

| www: | www.saimc.co.za |

| Articles: | More information and articles about SAIMC |

© Technews Publishing (Pty) Ltd | All Rights Reserved